I-Samarium Cobalt (SmCo) Magnets

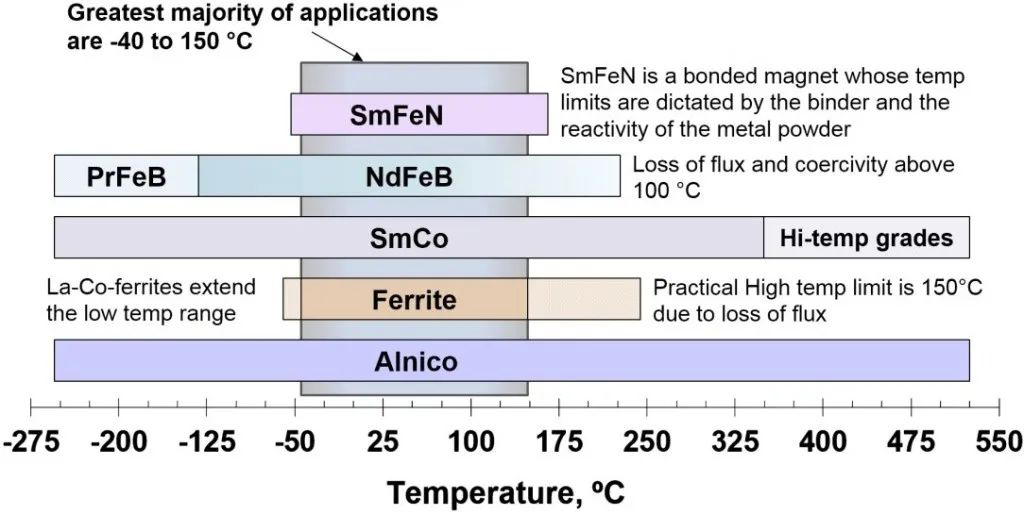

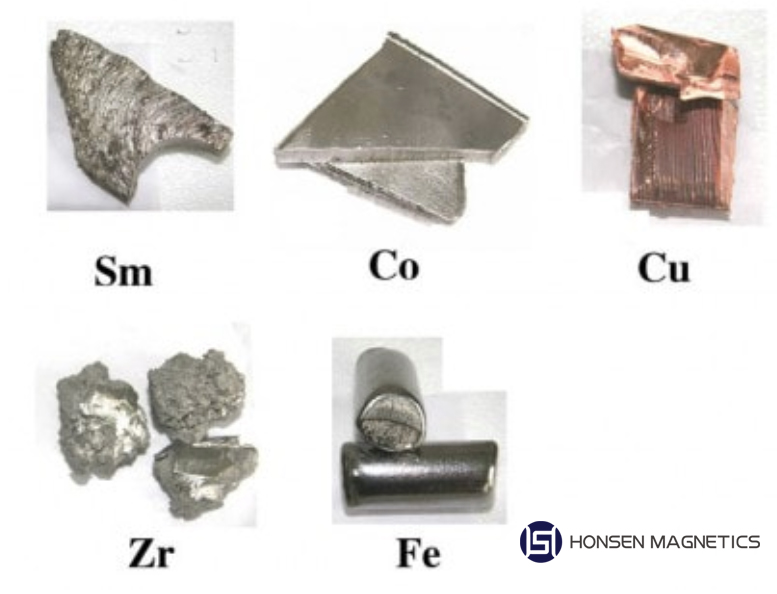

Ama-Samarium Cobalt Magnets (SmCo Magnets) awuhlobo lwezinto ezisebenza kahle zikazibuthe ezisebenza unomphela. Akhiqizwa kusetshenziswa i-metallic samarium, i-cobalt, nezinye izinsimbi ezingavamile, okuzenza zibe yimali kazibuthe ebiza kakhulu ukukhiqiza. Inqubo yokukhiqiza ibandakanya ukuncibilika, ukugaywa, ukucindezela, nokucwilisa, okuholela ezimpahleni ezihlukene kanye namabanga omazibuthe. Enye inzuzo ephawulekayo kamazibuthe be-SmCo ukumelana kwabo okuphezulu nokugqwala, kanye nekhono labo lokumelana nezinga lokushisa eliphezulu, lifinyelela ku-350 °C, futhi ngezinye izikhathi ngisho no-500 °C. Lokhu ukumelana nezinga lokushisa kubenza bahluke kwabanye odonsa unomphela abanokubekezelela okuphansi emazingeni okushisa okwedlulele, okunikeza ozibuthe be-SmCo unqenqema olubalulekile.

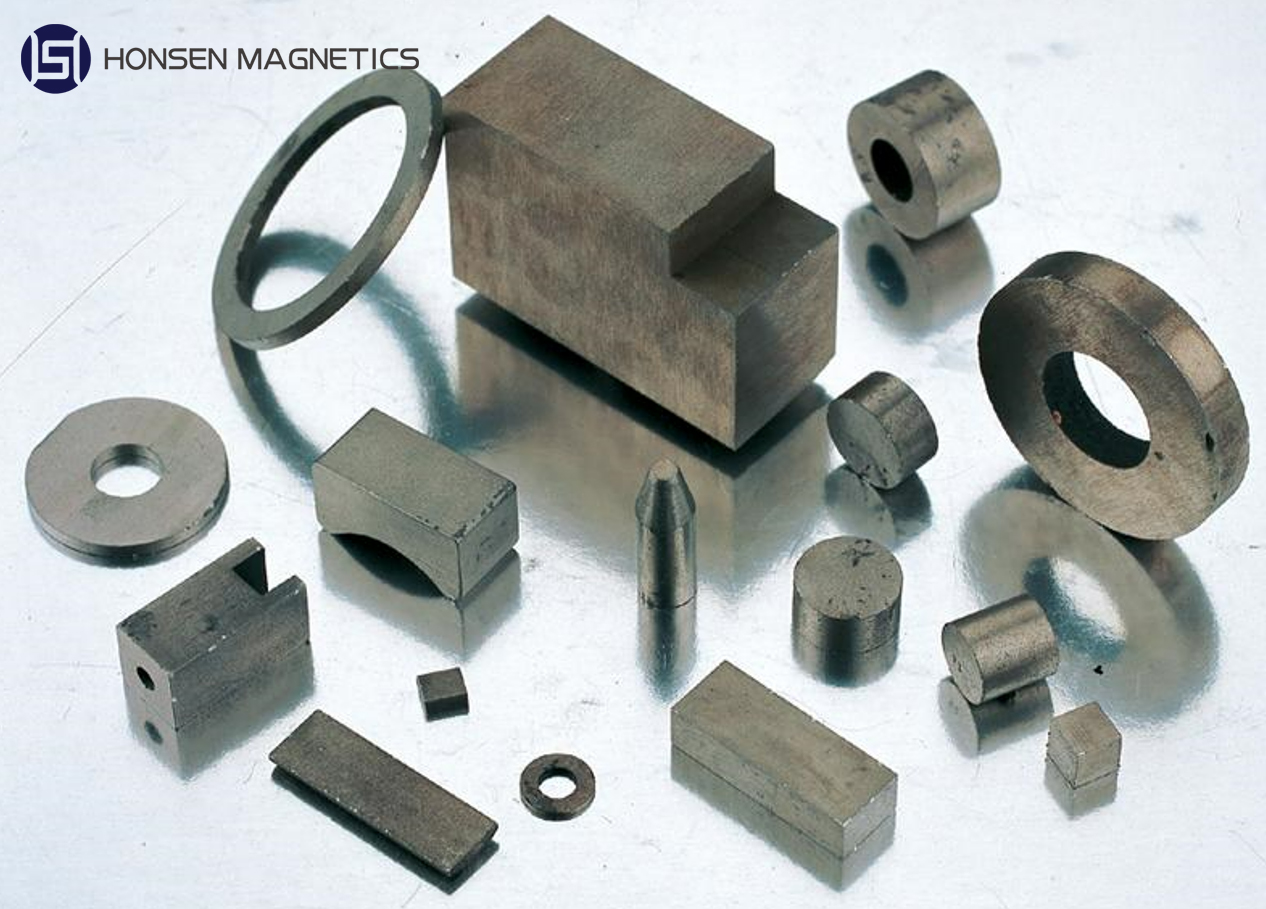

Njengokucaciswa kwekhasimende, ama-roughcasts we-SmCo Magnets azocutshungulwa ngomshini ukuze athole ukwakheka nosayizi oyifunayo. Ngaphandle uma kuyalwe ngenye indlela ikhasimende, imikhiqizo yokugcina izokwenziwa uzibuthe. Izinto zikazibuthe, ezinjengama-SmCo Magnets, zinozibuthe wemvelo futhi zibonisa imiphumela ehlukahlukene kazibuthe. Bayakwazi ukukhiqiza amandla kazibuthe wezinhlelo zokusebenza ezifana namamotho, imishini kazibuthe, izinzwa, namadivayisi we-microwave, phakathi kokunye. Ngokusebenza njengendlela yokudlulisa nokuguqula amandla kazibuthe abe amandla emishini namandla kagesi, izinto zikazibuthe zenza kube lula ukulawula futhi kuzuzwe imiphumela oyifunayo.

Ama-SmCo Magnets ayalingana ngamandlaI-Neodymium Magnetskodwa abe nokumelana nezinga lokushisa eliphezulu nokuphoqelela. Ama-SmCo Magnes ayisinqumo esikhethwayo sezinhlelo zokusebenza zemoto ezidinga kakhulu ngenxa yokumelana kwazo okuqinile nemithelela ye-demagnetization kanye nokuzinza okuhle kakhulu kokushisa. Njengama-Neodymium Magnets, i-SmCo Magnes nayo idinga ukumbozwa ukuvimbela ukugqwala. Kodwa-ke, ukumelana kwayo nokugqwala kungcono kakhulu kunokwe-NdFeB. Ezimweni ezine-acidic, i-SmCo Magnes kusafanele imbozwe. Ukumelana nokugqwala kwayo kunikeza isiqinisekiso kulabo abacabanga ukusebenzisa omazibuthe ezinhlelweni zezokwelapha.

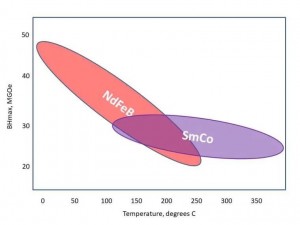

I-NdFeB Magnet yenza kahle emazingeni okushisa aphansi, kuyilapho i-SmCo Magnet yenza kahle emazingeni okushisa aphezulu. Ozibuthe be-Neodymium Iron Boron Magnets bangozibuthe abaqine kakhulu abangapheli ekamelweni lokushisa futhi bafika cishe ku-230 degrees Celsius, abalinganiswa ngozibuthe wabo oyinsalela we-Br. Kodwa amandla abo ehla ngokushesha ngokukhuphuka kwezinga lokushisa. Lapho izinga lokushisa lokusebenza lifinyelela ku-230 degrees Celsius, ukusebenza kwezibuthe ze-samarium cobalt kuqala ukudlula lokho kwe-NdFeB.

I-SmCo Magnet iyinto yesibili enamandla kazibuthe enekhono elihle kakhulu lokulwa nokukhishwa kazibuthe, esetshenziswa kabanzi embonini ye-aerospace noma izimboni lapho ukusebenza kubaluleke kakhulu futhi izindleko zisesibili. Ama-SmCo Magnets athuthukiswe ngawo-1970 anamandla kunawoOzibuthe BeCeramics (Ferrite Magnets)futhiIzibuthe ze-Aluminium Nickel Cobalt (Ozibuthe be-AlNiCo), kodwa hhayi njengokuqina njenge-Neodymium Magnets. Ama-Samarium Cobalt Magnets ahlukaniswe ikakhulukazi izigaba ezimbili, ahlukaniswe ububanzi bamandla. Ibanga lomkhiqizo wamandla weqembu lokuqala i-Sm1Co5 (eyaziwa nangokuthi 1-5) kanye nobubanzi beqembu lesibili i-Sm2Co17 (2-17).

I-Honsen Magneticsikhiqiza izinhlobo ezahlukene zeOzibuthe be-SmCo5 kanye ne-Sm2Co17.

Ukukhiqiza Inqubo SmCo Magnets

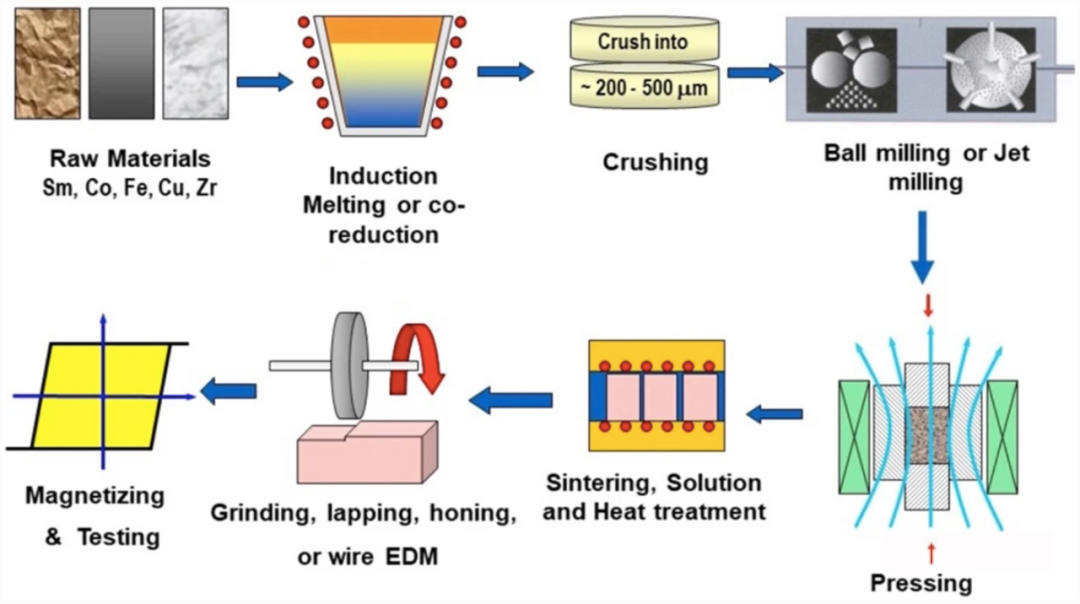

Ama-SmCo Magnets kanye Neodymium Magnets abelana ngenqubo yokukhiqiza efanayo. Ziqala njengezinsimbi eziyimpuphu, ezixutshwa futhi zihlanganiswe ngaphansi kwensimu enamandla kazibuthe. Izinto ezihlanganisiwe zibe sezifakwa emanzini ukuze kwakhiwe omazibuthe abaqinile. Uma kuziwa ekwenziweni komshini, zombili izinto zenza kube nesidingo sokusebenzisa amathuluzi edayimane, imishini yokukhipha ugesi, noma ukugaya okuhuquzelayo. Lezi zinqubo zibalulekile ukuze kuzuzwe umumo oyifunayo kanye nobukhulu odonsa. Inqubo yokukhiqiza omagnethi be-SmCo (Samarium Cobalt) ibandakanya izinyathelo ezimbalwa:

Inqubo yempushana→ Ukucindezela→ I-Sintering → Ukuhlolwa kwempahla kazibuthe → ukusika → imikhiqizo eqediwe

Ama-SmCo Magnets avame ukucutshungulwa ngaphansi kwezimo ezingenazibuthe, ngesondo lokugaya idayimane kanye nokugaya okumanzi, okudingekayo. Ngenxa yokushisa okuphansi kokushisa, i-SmCo Magnets akumele yome ngokuphelele. Inhlansi encane nje noma ugesi omile okhiqizwayo ungavusa kalula umlilo, ngezinga lokushisa eliphakeme kakhulu, okunzima ukulilawula.

Izici Eziyisisekelo SmCo Magnets

I-Demagnetization inzima kakhulu ku-samarium-cobalt

Omazibuthe be-SmCo bazinzile izinga lokushisa.

Ayabiza futhi angaphansi kokuguquguquka kwentengo (i-cobalt izwela intengo yemakethe).

Ozibuthe baseSamarium-cobalt banokugqwala okuphezulu kanye nokumelana ne-oxidation, abavamile ukumbozwa futhi bangase baqashwe.

Ozibuthe be-Samarium-cobalt bantekenteke futhi baqhekeka kalula futhi baqhekezwe.

Ozibuthe be-Samarium Cobalt abafakwe i-sintered babonisa i-anisotropy kazibuthe, ekhawulela ukuqondiswa kukazibuthe ku-eksisi yokuma kwawo kukazibuthe. Lokhu kufezwa ngokuvumelanisa isakhiwo sekristalu yezinto njengoba senziwa.

SmCo Magnets VS Sintered NdFeB Magnets

Okulandelayo umehluko omkhulu phakathi kozibuthe be-NdFeB abahlanganisiwe kanye nozibuthe be-SmCo:

1. Amandla kazibuthe:

Amandla kazibuthe we-Permanent Neodymium Magnet makhulu kunalawo we-SmCo Magnet. I-Sintered NdFeB ine-(BH)Max efika ku-55MGOe, kanti impahla ye-SmCo ine-(BH)Max engu-32MGOe. Uma kuqhathaniswa nempahla ye-NdFeb, impahla ye-SmCo ingcono ekumelaneni ne-demagnetization.

2. Ukumelana nezinga lokushisa eliphezulu

Mayelana nokumelana nezinga lokushisa eliphezulu, i-NdFeB ayingcono kune-SmCo. I-NdFeB ingakwazi ukumelana namazinga okushisa afika ku-230 °C kuyilapho i-SmCo ikwazi ukumelana nezinga lokushisa elifinyelela ku-350 °C.

3. Ukumelana nokugqwala

Ozibuthe be-NdFeB bazabalaza ukumelana nokugqwala kanye ne-oxidation. Ngokuvamile, zidinga ukupuletiswa noma zifakwe nge-vacuum ukuze zivikeleke. I-Zinc, i-nickel, i-epoxy, nezinye izinto zokumboza zivame ukusetshenziswa. Izibuthe ezenziwe nge-SmCo ngeke zigqwale.

4. Isimo, inqubo, kanye nokuhlanganisa

Ngenxa yobuthaka bazo, i-NdFeb ne-SmCo azikwazi ukukhiqizwa kusetshenziswa izinqubo zokusika ezijwayelekile. Isondo ledayimane kanye nokusika kwe-electrode yocingo yizindlela ezimbili eziyinhloko zokucubungula. Lokhu kunciphisa izinhlobo zalezi zidonsa ezingase zikhiqizwe. Izimo eziyinkimbinkimbi kakhulu azikwazi ukusetshenziswa. Izinto ze-SmCo zibhibha futhi ziphuka uma kuqhathaniswa nezinye izinto. Ngakho-ke, lapho wakha futhi usebenzisa omagnethi be-SmCo, sicela uqaphe ngokwedlulele.

5. Inani

Ozibuthe be-SmCo babebiza ngokuphindwe kabili uma bengabizi ngokuphindwe kathathu, njengozibuthe be-NdFeB eminyakeni embalwa edlule. Ngenxa yezinqubomgomo ezivimbelayo zezwe ezimayini ezingavamile, intengo ye-NdFeB inyuke kakhulu eminyakeni yamuva. Empeleni, omazibuthe be-NdFeB abajwayelekile babiza kancane kune-samarium cobalt.

Izicelo SmCo Magnets

Imelana ngokuqinile nokugqwala kanye ne-oxidation, iSmCo Magnets ithola ukusetshenziswa okubanzi emikhakheni yezindiza, i-aerospace, ukuvikela izwe, kanye nezempi, kanye nokukhiqizwa kwezingxenye ze-microwave, imishini yokwelapha, izinsimbi, kanye nemishini, kanye nezinhlobo ezihlukahlukene. yezinzwa kazibuthe, amaprosesa, amamotho, kanye nozibuthe abaphakamisayo. Ukusetshenziswa okufanayo kwezimboni kwe-NdFeB kufaka phakathi amaswishi, izipikha, izinjini zikagesi, izinsimbi, nezinzwa.

KUNGANI SIKHETHE

Ngaphezu kweminyaka eyishumi,I-Honsen Magneticsuphumelele kakhulu ekukhiqizeni nasekuhwebeniOzibuthe Abahlala PhakadefuthiImihlangano Yezibuthe. Imigqa yethu yokukhiqiza ihlanganisa izinqubo ezibalulekile ezinjengomshini, ukuhlanganisa, ukushisela, nokubumba umjovo, okusivumela ukuthi sinikeze isisombululo esibanzi kumakhasimende ethu. Ngamakhono ethu abanzi, siyakwazi ukukhiqiza imikhiqizo yekhwalithi ephezulu ehlangabezana namazinga aphezulu.

1. Siyakwazi ukukhiqiza izinhlobo eziningi zemikhiqizo ye-Samarium Cobalt ngezindlela ezihlukahlukene futhi sinezinto ezihlukahlukene.

2. Amakhono ethu okukhiqiza afinyelela ekukhiqizeni Izibuthe ze-SmCo ezinosayizi omkhulu, zonke zifakwe uzibuthe ukuze zibe namandla aphelele.

3. Sinobuchwepheshe obudingekayo kanye nezinsiza zokuqhuba ukukhiqizwa ngobuningi kozibuthe bezinga eliphezulu be-YXG-33H, abaziqhayisa nge-(BH)max engu-30-33MGOe.

4. Sinamandla okuhlinzeka ngozibuthe abaningi be-SmCo ngokuzinza, nokusebenza, futhi siphethe ukuphoqelelwa okuphezulu kwe-HK (HK≥18KOe).

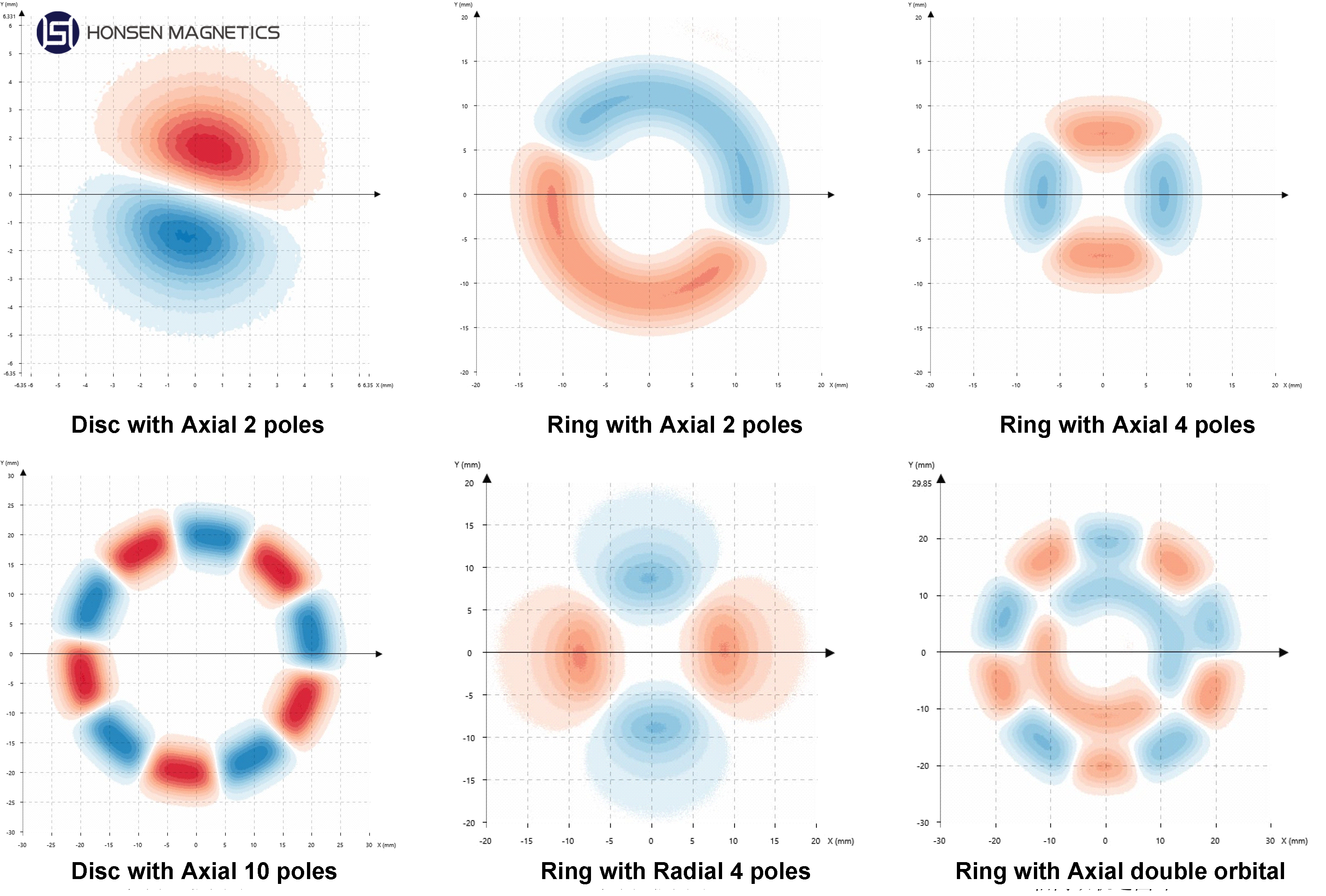

5. Singakwazi ukwenza omazibuthe ngezigxobo eziningi, kodwa kubalulekile ukuqaphela ukuthi ubukhulu bezibuthe akufanele budlule u-6mm.

6. Siyakwazi ukuhlinzeka ngozibuthe ngokuchezuka kukazibuthe okungaphansi kuka-1°, siqinisekisa ukunemba okukhethekile ekuqondaneni kwendawo kazibuthe.

7. Sinekhono lokwenza ngendlela oyifisayo imikhiqizo ye-SmCo yebanga le-YXG-35 ngomkhiqizo wamandla kazibuthe aphezulu kakhulu, ehlinzeka ngebanga le-Br elingu-11.6-12kGs kanye (BH) nobubanzi obungu-32-35MGOe. Lo mkhiqizo wamandla kazibuthe njengamanje uphakeme kakhulu embonini ye-samarium cobalt.

8. Sinikezela ngozibuthe be-SmCo enziwe ngokwezifiso abane-coefficient yezinga lokushisa eliphansi kakhulu (LTC) njengochungechunge lwe-YXG-18. Laba zibuthe babonisa ukuzinza okuhle kakhulu kwezinga lokushisa, ne-coefficient yezinga lokushisa le-Br ku-RT-100℃ ka -0.001%/℃.

9. Siphinde futhi sihlinzeke ngoZibuthe be-HT500 SmCo abangavimbeli izinga lokushisa eliphezulu abangalungiselelwa ukucaciswa kwakho. Lawa mamagnethi angakwazi ukumelana namazinga okushisa adlulele, anezinga lokushisa eliphakeme lokusebenza elingu-500℃.

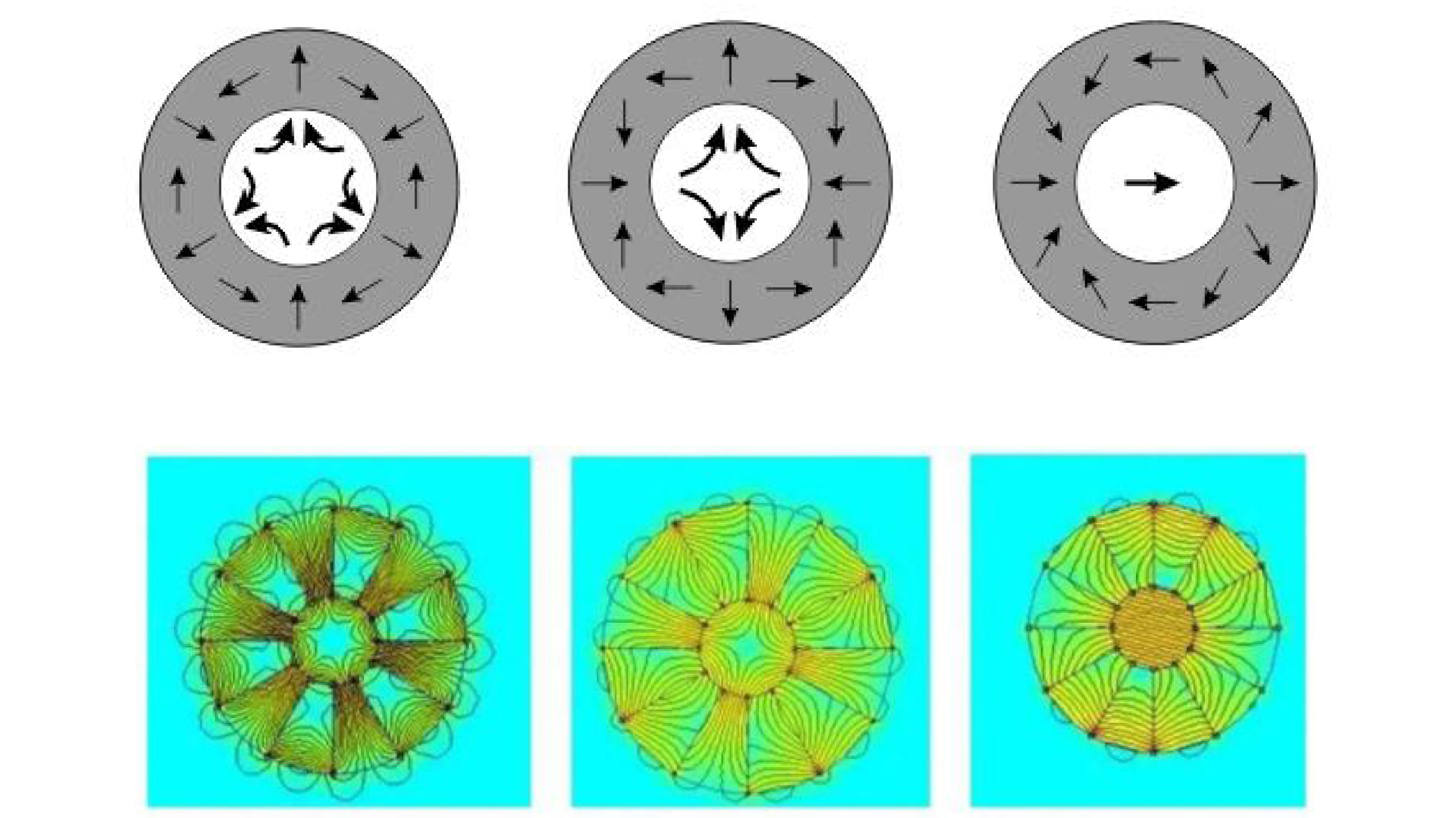

10. Sinekhono lokukhiqiza Ozibuthe be-SmCo ngezindlela ezihlukahlukene eziyinkimbinkimbi futhi sinikeze izinketho ze-multi-angle magnetization, kuhlanganise ne-Halbach Arrays.

I-Multipole Magnetization

Ukuchezuka kwe-engeli

I-Halbach Array

IZIKHUNGO ZOKUKHIQIZA

Sizibophezele ekunikezeni amakhasimende ethu ukwesekwa okusebenzayo kanye nemikhiqizo emisha, encintisanayo eqinisa ukuma kwethu emakethe. Sigqugquzelwa uguquko oluguquguqukayo kozibuthe nezingxenye ezihlala njalo, asigxilile ekuphishekeleni ukukhula kanye nokuhlola izimakethe ezintsha ngokusungula izinto ezintsha zobuchwepheshe. Ngaphansi kokuqondisa kukanjiniyela omkhulu, umnyango wethu we-R&D onesipiliyoni usebenzisa ubuchwepheshe bangaphakathi, uthuthukisa ubudlelwano bamakhasimende, futhi ulindele ngokujulile izitayela zemakethe. Amaqembu azimele angamela ngenkuthalo imisebenzi yomhlaba wonke, eqinisekisa ukuthuthuka okuqhubekayo kwamaphrojekthi ocwaningo.

IKHWALITHI NOKUPHEPHA

Ukuphathwa kwekhwalithi kuyisici esibalulekile sobunikazi bethu benkampani. Sibheka ikhwalithi njengokushaya kwenhliziyo nekhampasi yebhizinisi. Ukuzibophezela kwethu kudlulela ngalé kokusobala njengoba sihlanganisa isistimu yokuphatha ikhwalithi ephelele emisebenzini yethu. Ngale ndlela, siqinisekisa ukuthi imikhiqizo yethu ihlangabezana njalo futhi yeqa izimfuneko zamakhasimende ethu, okubonisa ukuzinikela kwethu ekwenzeni kahle okungenakuqhathaniswa.

UKUPAKASHA KWETHU

Siyakuqonda ukubaluleka kokupakishwa kwezinto ezibonakalayo kazibuthe, ikakhulukazi ngomoya nangolwandle. Izakhiwo eziyingqayizivele zezinto kazibuthe zidinga ukunakwa okukhethekile kanye nezinyathelo zokuphepha ukuze kuqinisekiswe ukulethwa kwazo okuphephile kumakhasimende. Ukuze sihlangabezane nalezi zidingo, senze inqubo yokupakisha eqinile eyenzelwe ngokukhethekile imikhiqizo kazibuthe. Izinto zethu zokupakisha zikhethwe ngokucophelela ukuze zinikeze isivikelo esiphelele ezintweni zangaphandle njengokushaqeka, umswakama, nokuphazamiseka kazibuthe. Sisebenzisa inhlanganisela yamabhokisi ekhadibhodi ahlala isikhathi eside, iziphedi zegwebu, nezinto ezilwa nokuqina ukuze sivikele ubuqotho bemikhiqizo kazibuthe ngesikhathi sokuthunyelwa. Ukwengeza, sisebenzisa izinyathelo eziqinile zokulawula ikhwalithi ukuze siqinisekise ukuthi umkhiqizo ngamunye opakishiwe uhlangabezana namazinga ethu aphezulu.

Ngokuthatha izinyathelo zokuphepha ezengeziwe ekufakweni kwezinto zikazibuthe, sihlose ukunciphisa ubungozi bokulimala, siqinisekise ubude bemikhiqizo yethu, futhi ekugcineni sikhulise ukwaneliseka kwamakhasimende. Sikholelwa ukuthi ukupakisha okufanele kuyingxenye ebalulekile yokuzibophezela kwethu ekuletheni ngokuphepha nangempumelelo imikhiqizo kazibuthe yekhwalithi ephezulu kumakhasimende ethu, kungakhathaliseki indlela yokuthutha.