Izinhlobo ezahlukene zemagnethi zihlanganisa:

Alnico Magnets

Ozibuthe be-Alnico bakhona ezinguqulweni zabalingisi, ze-sintered, nezihlanganisiwe. Okuvame kakhulu ngozibuthe be-alnico. Bayiqembu elibaluleke kakhulu lama-alloy kazibuthe ahlala njalo. Ozibuthe be-alnico baqukethe i-Ni, A1, Fe, ne-Co enezengezo ezincane ze-Ti ne-Cu. Ama-alnico anokucindezela okuphezulu kakhulu ngenxa yesimo se-anisotropy yezinhlayiya ze-Pe noma ze-Fe, Co. Lezi zinhlayiya zenziwa ku-matrix ye-Ni—Al ene-ferromagnetic ebuthaka noma engeyona i-ferromagnetic. Ngemuva kokupholisa, i-isotropic alnicos 1-4 ifakwe amahora ambalwa ekushiseni okuphezulu.

Ukubola kwe-Spinodal kuyinqubo yokuhlukaniswa kwesigaba. Ubukhulu bokugcina kanye nokuma kwezinhlayiya kunqunywa ezigabeni zokuqala zokubola kwe-spinodal. Ama-Alnico anama-coefficients okushisa angcono kakhulu ngakho-ke ekushintsheni kwezinga lokushisa anoshintsho oluncane ekukhishweni kwenkambu. Lezi zibuthe zingasebenza emazingeni okushisa aphezulu kunanoma yimuphi uzibuthe.

I-Demagnetization yama-alnicos ingancishiswa uma indawo yokusebenza ithuthukiswa, njengokusebenzisa uzibuthe omude kunangaphambili ukuze kwandiswe isilinganiso sobude nobubanzi obuwumthetho omuhle wegayidi yesithupha yomazibuthe be-Alnico. Zonke izinto ezikhipha uzibuthe zangaphandle kufanele zicatshangelwe nokho. Isilinganiso esikhulu sobude ukuya kobubanzi kanye nokujikeleza kazibuthe okuhle kungase kudingeke.

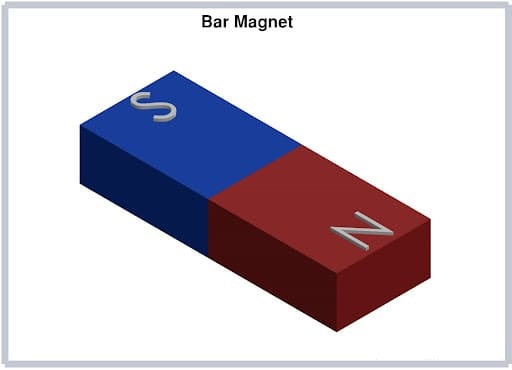

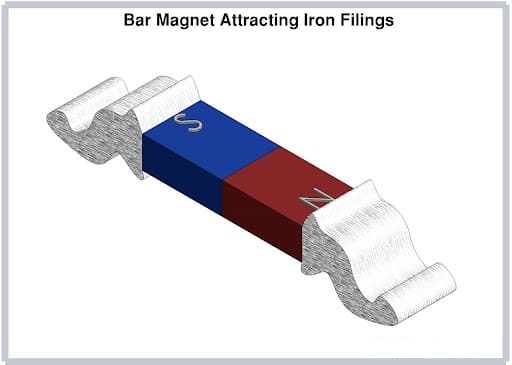

Izibuthe Zebha

Ozibuthe bebha izingcezu zezinto eziwunxande, ezakhiwe ngensimbi, insimbi nanoma iyiphi enye into ye-ferromagnetic enezici noma izici ezinamandla kazibuthe. Akhiwe ngezigxobo ezimbili, isigxobo sasenyakatho nesigxobo saseningizimu.

Lapho uzibuthe webha imisiwe ngokukhululeka, iyaziqondanisa ukuze isigxobo sasenyakatho sibheke ngasengxenyeni yesigxobo sikazibuthe sasenyakatho somhlaba.

Kunezinhlobo ezimbili zomazibuthe bebha. Ozibuthe bebha ye-cylindrical babizwa nangokuthi omazibuthe benduku futhi banogqinsi oluphakeme kakhulu kububanzi obuvumela impahla yabo ephakeme ye-magnetism. Iqembu lesibili lomazibuthe bamabha ama-rectangular bar magnets. Lezi zibuthe zithola izinhlelo zokusebenza eziningi emikhakheni yokukhiqiza nezobunjiniyela njengoba zinamandla kazibuthe kanye nenkundla enkulu kunamanye amamagnethi.

Uma uzibuthe webha ephukile phakathi nendawo, zombili izingcezu zisazoba nesigxobo sasenyakatho nesigxobo esiseningizimu, noma ngabe lokhu kuphindwa izikhathi ezimbalwa. Amandla kazibuthe webha anamandla kakhulu esigxotsheni. Lapho omazibuthe ababili bebha besondezwa komunye nomunye, izigxobo zabo ezingafani ziyaheha futhi njengezigxobo zizoxoshana. Ozibuthe bebha baheha izinto ezisebenza nge-ferromagnetic njenge-cobalt, i-nickel, nensimbi.

Ozibuthe Abahlanganisiwe

Ozibuthe abahlanganisiwe banezingxenye ezimbili eziyinhloko: i-polymer engeyona-magnetic kanye nempushana kazibuthe eqinile. Lesi sakamuva singenziwa kuzo zonke izinhlobo zezinto kazibuthe, okuhlanganisa i-alnico, i-ferrite ne-neodymium, i-cobalt nensimbi. Izimpushana kazibuthe ezimbili noma ngaphezulu zingaxutshwa ndawonye ngaleyo ndlela kwakhiwe ingxube eyingxube yempushana. Izici zempushana zenziwa ngokucophelela ngokusebenzisa ikhemistri kanye nokucubungula isinyathelo ngesinyathelo okuhloswe ngaso ukusebenzisa uzibuthe oboshiwe kungakhathaliseki ukuthi ziyini izinto.

Ozibuthe abahlanganisiwe banezinzuzo eziningi ngokuthi ukukhiqizwa kwesimo senetha esiseduze akudingi noma imisebenzi yokuqedela ephansi uma kuqhathaniswa nezinye izinqubo ze-metallurgical. Ngakho-ke imihlangano ye-value added ingenziwa ngokwezomnotho ekusebenzeni okukodwa. Lawa mamagnethi ayinto eguquguqukayo kakhulu futhi aqukethe izinketho eziningi zokucubungula. Ezinye izinzuzo zozibuthe ababoshiwe ukuthi banezakhiwo ezinhle kakhulu zokusebenzisa ugesi kanye nokumelana nogesi okukhulu uma kuqhathaniswa nezinto ezihlanganisiwe. Lezi zidonsa ziyatholakala futhi ngamasayizi ahlukene ayinkimbinkimbi kanye nokuma. Banokubekezelelana okuhle kwejometri ngokusebenza okuphansi kakhulu kwesibili. Ziyatholakala futhi nge-multipole magnetization.

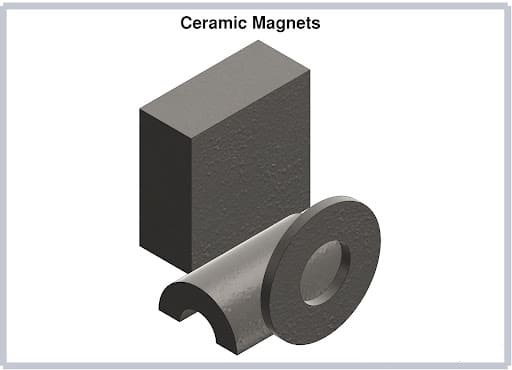

Izibuthe Ze-Ceramic

Igama elithi uzibuthe we-ceramic libhekisela kuzibuthe zeFerrite. Lezi zibuthe ze-ceramic ziyingxenye yomndeni wamagnetic unomphela. Ziyizindleko eziphansi kakhulu ezitholakalayo uma ziqhathaniswa nabanye odonsa. Izinto ezenza izibuthe ze-ceramic ziyi-iron oxide ne-strontium carbonate. Lawa mamagnethi e-ferrite anesilinganiso samandla kazibuthe aphakathi nendawo futhi angasetshenziswa emazingeni okushisa aphezulu. Enye inzuzo ekhethekile abanayo ukuthi iyakwazi ukumelana nokugqwala futhi kulula kakhulu ukwenza uzibuthe, okubenza babe yisinqumo sokuqala kubathengi abaningi, izicelo zezimboni, ezobuchwepheshe nezohwebo. Ozibuthe be-Ceramic banamabanga ahlukene kanti abajwayele ukusetshenziswa yiBanga lesi-5. Batholakala ngezindlela ezihlukene njengamabhuloki namajamo amandandatho. Angase futhi enziwe ngokwezifiso ukuze ahlangabezane nezidingo eziqondile zekhasimende.

Ozibuthe beFerrite bangasetshenziswa emazingeni okushisa aphezulu. Izici zikazibuthe zikazibuthe we-ceramic zehla ngezinga lokushisa. Zidinga namakhono akhethekile okwenza imishini. Enye inzuzo eyengeziwe ukuthi awadingi ukuvikelwa ekugqwaleni okungaphezulu ngoba ahlanganisa ifilimu yempushana kazibuthe ebusweni bawo. Ekuhlanganisweni, kuvame ukunamathiselwa emikhiqizweni ngokusebenzisa ama-superglues. Ozibuthe BeCeramic bashwabene futhi baqinile, baphuka kalula uma bewisiwe noma bephihlizwa ndawonye, ngakho ukuqapha nokunakekela kuyadingeka lapho ubamba lawa mamagnethi.

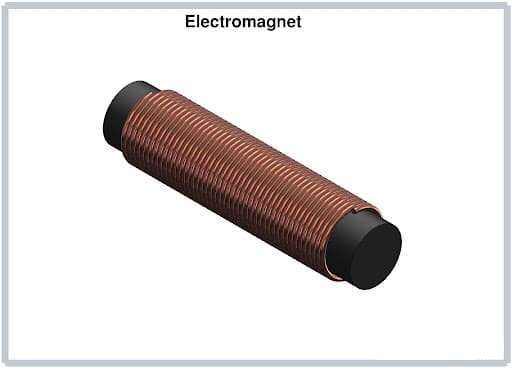

Amazibuthe kagesi

Ama-electromagnets yizibuthe lapho amandla kagesi abangela khona amandla kazibuthe. Ngokuvamile ahlanganisa ucingo olufakwa ikhoyili. Umsinga udala insimu kazibuthe ngocingo. Lapho i-current icishiwe insimu kazibuthe iyanyamalala. Ama-electromagnets ahlanganisa izintambo eziphendukayo ezivame ukuzungeza inkaba kazibuthe eyenziwe nge-ferromagnetic field. I-magnetic flux igxilwe yi-magnetic core, ikhiqiza uzibuthe onamandla kakhulu.

Inzuzo kazibuthe kagesi uma kuqhathaniswa nezibuthe ezihlala njalo ukuthi ushintsho lungasetshenziswa ngokushesha endaweni kazibuthe ngokulawula amandla kagesi ekujikeni. Kodwa-ke, i-drawback enkulu yama-electromagnets ukuthi kunesidingo sokuhlinzekwa okuqhubekayo kwamandla wamanje ukuze kugcinwe insimu kazibuthe. Okunye okuyizihibe ukuthi zishisa ngokushesha futhi zidle amandla amaningi. Ziphinde zikhiphe amandla amakhulu endaweni yazo kazibuthe uma kukhona ukuphazamiseka kwamandla kagesi. Lezi zidonsa zivame ukusetshenziswa njengezingxenye zemishini kagesi ehlukahlukene, njengamajeneretha, ama-relay, ama-electro-mechanical solenoid, amamotho, izipikha, kanye nemishini yokuhlukanisa kazibuthe. Okunye ukusetshenziswa okuhle embonini ukuhambisa izinto ezisindayo nokucosha insimbi nensimbi. Ezinye izici ezimbalwa zama-electromagnets ukuthi ama-magnets aheha izinto ze-ferromagnetic ezifana ne-nickel, i-cobalt, ne-iron futhi njengamazibuthe amaningi afana nezigxobo zisuka komunye nomunye kuyilapho izigxobo ezingafani zidonselana.

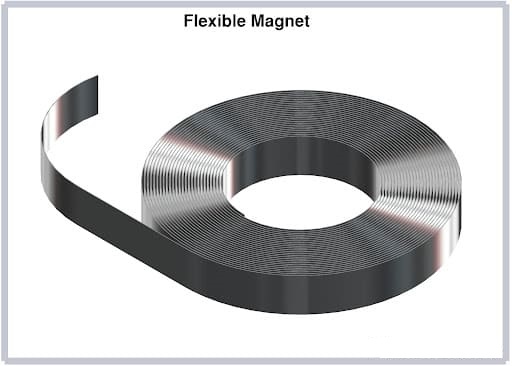

Ozibuthe Abaguquguqukayo

Ozibuthe abaguquguqukayo bayizinto kazibuthe eziklanyelwe ukugoba ngaphandle kokuphuka noma ukusekela umonakalo. Lezi zibuthe aziqinile noma aziqini, kodwa empeleni zingagoba. Le engenhla eboniswe kumfanekiso 2:6 ingase isongwe. Lawa kazibuthe ahlukile ngoba abanye omazibuthe abakwazi ukugoba. Ngaphandle uma kuwuzibuthe oguquguqukayo, ngeke agobe ngaphandle kokonakala noma ukuphuka. Ozibuthe abaningi abaguquguqukayo bane-substrate yokwenziwa enongqimba oluncane lwempushana ye-ferromagnetic. I-substrate ingumkhiqizo wezinto eziguquguqukayo kakhulu, njenge-vinyl. I-substrate yokwenziwa iba kazibuthe lapho i-ferromagnetic powder isetshenziswa kuyo.

Izindlela eziningi zokukhiqiza zisetshenziselwa ukukhiqiza lezi zibuthe, nokho cishe zonke zibandakanya ukusetshenziswa kwempushana ye-ferromagnetic ku-substrate yokwenziwa. Impushana ye-ferromagnetic ixutshwa kanye ne-ejenti enamathelayo enamathelayo ize inamathele ku-substrate yokwenziwa. Ozibuthe abaguquguqukayo bafika ngezinhlobo ezahlukene ngokwesibonelo amashidi emiklamo ehlukene, umumo, nosayizi abavame ukusetshenziswa. Izimoto, iminyango, amakhabethe ensimbi nezakhiwo zisebenzisa lezi zibuthe eziguquguqukayo. Lezi zidonsa ziyatholakala futhi ngamapheshana, amapheshana mancane futhi made uma kuqhathaniswa namashidi.

Emakethe zivame ukudayiswa futhi zipakishwe emiqulu. Ozibuthe abaguquguqukayo bashintshashintsha ngezinto zabo ezigobekayo futhi bangakwazi ukugoqa imishini kalula kanjalo nezinye izindawo nezingxenye. Uzibuthe oguquguqukayo usekelwa ngisho nezindawo ezingasheleli kahle noma eziyisicaba. Ozibuthe abaguquguqukayo bangasikwa futhi balolongelwe babe yizimo nosayizi oyifunayo. Iningi lazo linganqunywa ngisho nangethuluzi lokusika lendabuko. Ozibuthe abaguquguqukayo abathinteki ngokubhoboza, ngeke baqhekeke kodwa bazokwakha izimbobo ngaphandle kokulimaza izinto ezizungezile kazibuthe.

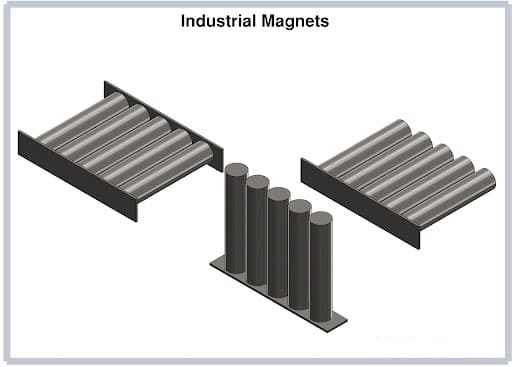

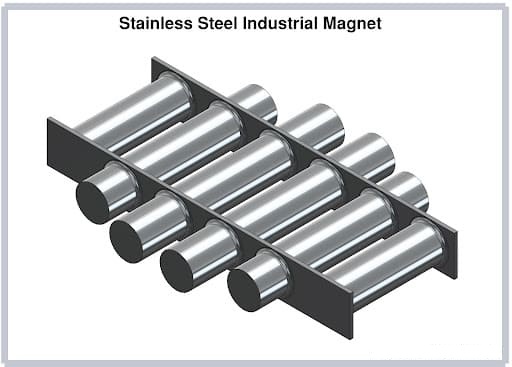

Izibuthe Zezimboni

I-Industrial magnet inguzibuthe onamandla kakhulu osetshenziswa emkhakheni wezimboni. Ziyakwazi ukuzivumelanisa nezinhlobo ezahlukene zemikhakha futhi zingatholakala kunoma yisiphi isimo noma usayizi. Zibuye zidume ngamamaki azo amaningi kanye nezimfanelo zokugcina izakhiwo ze-residual magnetism. Ozibuthe bezimboni ezihlala njalo bangenziwa nge-alnico, umhlaba ongavamile, noma i-ceramic. Zingozibuthe abenziwe ngento eyi-ferromagnetic eyenziwe uzibuthe yinkundla kazibuthe yangaphandle, futhi ekwazi ukuba sesimweni sikazibuthe isikhathi eside. Ozibuthe basezimbonini bagcina isimo sabo ngaphandle kosizo lwangaphandle, futhi bahlanganisa izigxobo ezimbili ezibonisa ukukhuphuka kwamandla eduze nezigxobo.

Ozibuthe baseSamarium Cobalt Industrial bangakwazi ukumelana namazinga okushisa afinyelela ku-250 °C. Laba zibuthe bamelana kakhulu nokugqwala njengoba bengenazo izakhi zensimbi kubo. Kodwa-ke lolu hlobo lukazibuthe lubiza kakhulu ukukhiqiza ngenxa yezindleko eziphezulu zokukhiqiza i-cobalt. Njengoba ozibuthe be-cobalt beyifanele imiphumela abayikhiqizayo yamandla kazibuthe aphakeme kakhulu, izibuthe zezimboni ze-samarium cobalt zivame ukusetshenziswa emazingeni okushisa aphezulu okusebenza, futhi zenze izinjini, izinzwa, namajeneretha.

I-Alnico Industrial Magnet iqukethe inhlanganisela enhle yezinto eziyi-aluminium, i-cobalt, ne-nickel. Lawa kazibuthe angase ahlanganise nethusi, insimbi, ne-titanium. Uma kuqhathaniswa neyangaphambili, omagnethi be-alnico bayakwazi ukumelana nokushisa futhi bangakwazi ukumelana namazinga okushisa aphakeme kakhulu afika ku-525 °C. Alula futhi ukuwenza demagnetize ngoba azwela kakhulu. I-Industrial Electromagnets iyalungiseka futhi ingavulwa futhi icishwe.

Ozibuthe bezimboni bangaba nokusetshenziswa okufana nalokhu:

Asetshenziselwa ukuphakamisa amashidi ensimbi, insimbi, kanye nezingcwecwe zensimbi. Lawa mamagnethi aqinile asetshenziswa ezinkampanini eziningi ezikhiqizayo njengamadivayisi kazibuthe anamandla amakhulu enza umsebenzi wezisebenzi ube lula. Umazibuthe wezimboni ubekwa phezu kwento bese kuthi ngemuva kwalokho i-magnetis ivulwe ukuze ibambe into bese idlulisela endaweni oyifunayo. Ezinye zezinzuzo zokusebenzisa izibuthe eziphakamisa izimboni ukuthi kunengozi ephansi kakhulu yezinkinga zemisipha namathambo phakathi kwabasebenzi.

Ukusebenzisa lezi zidonsa zezimboni kusiza abasebenzi bokukhiqiza ukuthi bazivikele ekulimaleni, kususe isidingo sokuthwala izinto ezisindayo. Ozibuthe basezimbonini bathuthukisa ukukhiqiza ezinkampanini eziningi ezikhiqizayo, ngenxa yokuthi ukuphakamisa nokuthwala izinto ezisindayo mathupha kudla isikhathi futhi kuqeda amandla kubasebenzi, ukukhiqiza kwabo kuthinteka kakhulu.

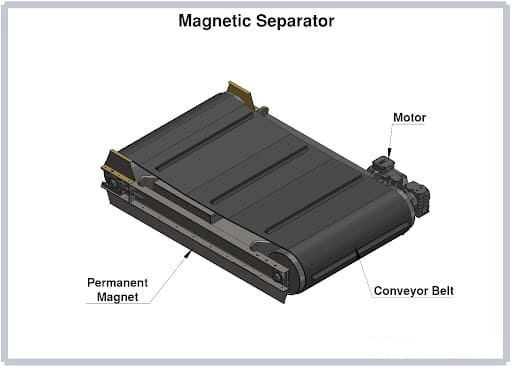

Ukuhlukaniswa Kwamagnetic

Inqubo yokuhlukanisa kazibuthe ihlanganisa ukuhlukanisa izingxenye zezingxube ngokusebenzisa uzibuthe ukuheha izinto kazibuthe. Ukuhlukaniswa kwamagnetic kuwusizo kakhulu ekukhetheni amaminerali ambalwa ayi-ferromagnetic, okungamaminerali aqukethe i-cobalt, insimbi, ne-nickel. Izinsimbi eziningi, okuhlanganisa isiliva, i-aluminium, negolide akuzona kazibuthe. Izinhlobonhlobo ezinkulu kakhulu zezindlela zemishini zivame ukusetshenziswa ukuhlukanisa lezi zinto kazibuthe. Phakathi nenqubo yokuhlukanisa kazibuthe, odonsa bahlelwa ngaphakathi kwezigubhu ezimbili ezihlukanisayo eziqukethe uketshezi, ngenxa yamazibuthe, izinhlayiya kazibuthe ziqhutshwa ukunyakaza kwesigubhu. Lokhu kudala ukugxila kazibuthe ngokwesibonelo i-ore concentrate.

Inqubo yokuhlukanisa kazibuthe iphinde isetshenziswe kuma-cranes kagesi ahlukanisa izinto zikazibuthe ezintweni ezingafuneki. Lokhu kuveza ukusetshenziswa kwayo ekulawuleni udoti kanye nemishini yokuthumela. Izinsimbi ezingadingekile nazo zingahlukaniswa nezimpahla ngale ndlela. Zonke izinto zokwakha zigcinwa zihlanzekile. Izikhungo ezahlukahlukene zokugaywa kabusha kanye nezikhungo zisebenzisa ukuhlukaniswa kazibuthe ukususa izingxenye ekugayweni kabusha, izinsimbi ezihlukene, kanye nokuhlanza insimbi, ama-pulley kazibuthe, odonsa abaphezulu, nezigubhu kazibuthe kwakuyizindlela zomlando zokugaywa kabusha embonini.

Ukuhlukaniswa kwamagnetic kuyasiza kakhulu ensimbi yezimayini. Lokhu kungenxa yokuthi insimbi ikhangwa kakhulu uzibuthe. Le ndlela iphinde isetshenziswe ezimbonini zokucubungula ukuhlukanisa ukungcola kwensimbi emikhiqizweni. Le nqubo ibalulekile futhi ezimbonini zokwenza imithi kanye nezimboni zokudla. Indlela yokuhlukanisa kazibuthe isetshenziswa kakhulu ezimeni lapho kunesidingo sokuqapha ukungcola, ukulawula ukungcola, kanye nokucutshungulwa kwamakhemikhali. Indlela yokuhlukanisa kazibuthe ebuthaka iphinde isetshenziselwe ukukhiqiza imikhiqizo ehlakaniphile enothe ngensimbi engasetshenziswa kabusha. Le mikhiqizo inamazinga aphansi kakhulu okungcola kanye nomthwalo wensimbi ophezulu.

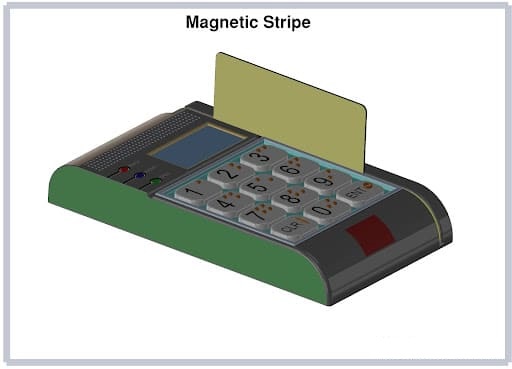

I-Magnetic Stripe

Ubuchwepheshe bemigqa kazibuthe buvumele idatha ukuthi igcinwe ekhadini lepulasitiki. Lokhu kufinyelelwe ngokushaja izingcezu ezincane ngozibuthe ngaphakathi komugqa kazibuthe ohlangothini olulodwa lwekhadi. Lobu buchwepheshe bemigqa kazibuthe buholele ekwakhiweni kwamamodeli ekhadi lesikweletu neledebhithi. Lokhu kuthathe indawo enkulu yokuthengiselana ngemali emazweni ahlukahlukene emhlabeni jikelele. Umugqa wamagnetic ungabuye ubizwe ngokuthi i-magstripe. Ukwakhiwa kwamakhadi omugqa kazibuthe anokuqina okuphezulu kakhulu nobuqotho bedatha obungayekethisi, izikhungo zezezimali namabhange akwazile ukwenza zonke izinhlobo zemisebenzi nezinqubo ezisekelwe ekhadini.

Imigqa kazibuthe inenani elingenakubalwa lokuthengiselana nsuku zonke futhi yenziwa yaba usizo ezinhlotsheni eziningi zamakhadi okuhlonza. Abantu abangochwepheshe bokufunda amakhadi bakuthola kulula ukukhipha imininingwane ngokushesha ekhadini likazibuthe, elibe selithunyelwa ebhange ukuze ligunyazwe. Kodwa-ke, eminyakeni edlule, ubuchwepheshe obusha be-brand buye banda ekuthengiseni amakhadi kazibuthe. Ochwepheshe abaningi babhekisela kule ndlela yesimanje njengohlelo lokukhokha ngaphandle kokuthinta ngoba luhilela izimo lapho imininingwane yokwenziwe ingase idluliswe, hhayi ngomugqa kazibuthe, kodwa ngamasignali athunyelwa ku-chip encane. Inkampani i-Apple Inc. isungule izinhlelo zokukhokha ngaphandle kokuthinta.

I-Neodymium Magnets

Lezi zibuthe zomhlaba eziyivelakancane zingozibuthe ezihlala njalo. Bakhiqiza amandla kazibuthe aqine kakhulu, futhi Inkundla kazibuthe ekhiqizwa yilaba zibuthe be-neodymium ingaphezu kwama-tesla angu-1.4. Ozibuthe be-Neodymium banezinhlelo zokusebenza eziningi ezichazwe ngezansi. Asetshenziswa ekwenzeni ama-hard disk drive aqukethe amathrekhi namasegimenti anamaseli kazibuthe. Wonke lawa maseli asebenza ngozibuthe noma nini lapho idatha ibhalwa kudrayivu. Okunye ukusetshenziswa kwalawa ma-magnets kusezipikha, ama-headphone, imibhobho nama-earphone.

Amakhoyili aphethe njengamanje atholakala kule mishini asetshenziswa kanye nozibuthe abangapheli ukushintsha ugesi ube amandla emishini. Olunye uhlelo lokusebenza ukuthi omazibuthe abancane be-neodymium basetshenziswa kakhulu ukubeka amazinyo okufakelwa endaweni yawo. Lezi zidonsa zisetshenziswa ezakhiweni zokuhlala nezokuhwebelana eminyango ngezizathu zokuphepha nokuvikeleka okuphelele. Okunye ukusetshenziswa okungokoqobo kwalawa zibuthe ukwenza ubucwebe bezokwelapha, imigexo, nobucwebe. Ozibuthe be-Neodymium basetshenziswa kakhulu njengama-anti-lock brake sensors, lawa ma-anti-lock brakes afakwa ezimotweni nasezimotweni eziningi.

Isikhathi sokuthumela: Jul-05-2022