Ibha Yesihlungi Samagnetic

Ibha yokuhlunga kazibuthe iyithuluzi elivame ukusetshenziselwa ukuhlanza ukungcola oketshezini namagesi. Leli thuluzi ngokuvamile liqukethe induku kazibuthe eyodwa noma ngaphezulu ezithwebula futhi zihlunge ukungcola emigqeni yoketshezi noma yegesi ukuvikela okokusebenza emonakalweni.

Izinti zokuhlunga kazibuthe zingakwazi ukuhlunga uketshezi, amagesi, izimpushana nezinto eziqinile. Kungakhathaliseki ukuthi iphatha amanzi, amafutha, amafutha noma isitashi, ingilazi, amaminerali, njll., ingathola imiphumela emihle.

Izinti zokuhlunga kazibuthe zinokuhluza okuhle kahle. Ngenxa ye-adsorption yayo kazibuthe, ingakwazi ukuhlunga ukungcola okuncane ngempumelelo, ngaleyo ndlela ithuthukise ikhwalithi nokuhlanzeka kwemikhiqizo.

Izinti zokuhlunga kazibuthe kulula ukuzihlanza, ukuzinakekela nokufaka esikhundleni. Ngenxa yesakhiwo sayo esilula, singahlakazwa kalula futhi sihlanzwe ukuze sigcine ukusetshenziswa kahle. Uma idinga ukushintshwa, vele umisele ibha yokuhlunga kazibuthe.

Izinti zokuhlunga kazibuthe ziyonga futhi ziyasebenza. Uma kuqhathaniswa nezihlungi ezivamile, izihlungi zokuhlunga kazibuthe azidingi amandla engeziwe noma izindleko futhi zingenza imisebenzi yokuhlunga ngokushesha nangempumelelo, ngaleyo ndlela zinciphise izindleko zokukhiqiza nokwandisa umkhiqizo.

Izicaciso Zebha Yesihlungi Sezibuthe

Usayizi: Usayizi wezinduku zokuhlunga kazibuthe kufanele zikhethwe ngokuya ngosayizi wepayipi kanye nezidingo zokugeleza. Usayizi uvame ukuchazwa ngamapharamitha afana nobude nobubanzi.

| Into No. | Ububanzi (mm) | Ubude (mm) | I-Surface Flux (Gauss) | Into No. | Ububanzi (mm) | Ubude (mm) | I-Surface Flux (Gauss) |

| 25×100 | 25 | 100 | 1500-14000GS | 25×600 | 25 | 600 | 1500-14000GS |

| 25×150 | 25 | 150 | 1500-14000GS | 25×650 | 25 | 650 | 1500-14000GS |

| 25×200 | 25 | 200 | 1500-14000GS | 25×700 | 25 | 700 | 1500-14000GS |

| 25×250 | 25 | 250 | 1500-14000GS | 25×750 | 25 | 750 | 1500-14000GS |

| 25×300 | 25 | 300 | 1500-14000GS | 25×800 | 25 | 800 | 1500-14000GS |

| 25×350 | 25 | 350 | 1500-14000GS | 25×850 | 25 | 850 | 1500-14000GS |

| 25×400 | 25 | 400 | 1500-14000GS | 25×900 | 25 | 900 | 1500-14000GS |

| 25×450 | 25 | 450 | 1500-14000GS | 25×950 | 25 | 950 | 1500-14000GS |

| 25×500 | 25 | 500 | 1500-14000GS | 25×1000 | 25 | 1000 | 1500-14000GS |

| 25×550 | 25 | 550 | 1500-14000GS | 25×1500 | 25 | 1500 | 1500-14000GS |

Izinga lokushisa: Impahla nezindlu zebha yokuhlunga kazibuthe kufanele ikwazi ukumelana nezinga lokushisa eliphezulu noma eliphansi lendawo yohlelo lokusebenza.

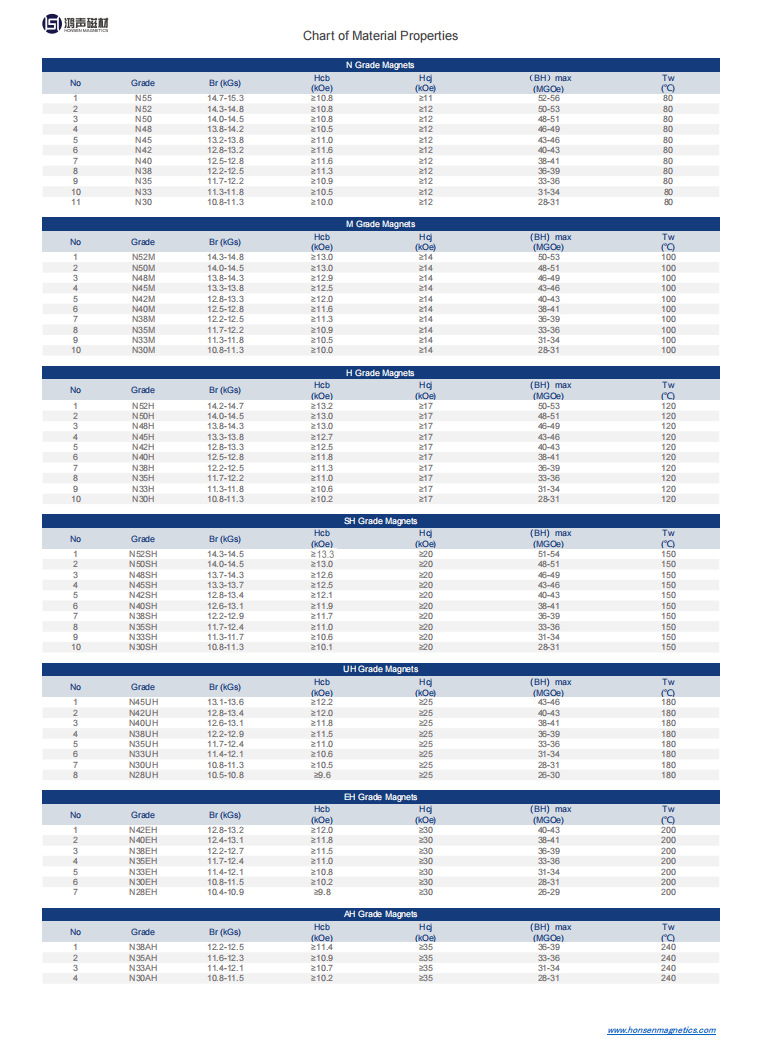

| Ibanga | Ubukhulu. ukusebenza Temp | I-Curie Temp | Ibanga lamagnetic elisekelwayo |

| N | 80℃/176℉ | 310℃/590℉ | I-N30-N55 |

| M | 100℃/212℉ | 340℃/644℉ | I-N30M-N52M |

| H | 120℃/248℉ | 340℃/644℉ | I-N30H-N52H |

| SH | 150℃/302℉ | 340℃/644℉ | I-N30SH-N52SH |

| UH | 180℃/356℉ | 350℃/662℉ | I-N28UH-N45UH |

| Eh | 200℃/392℉ | 350℃/662℉ | I-N28EH-N42EH |

| AH | 240℃/464℉ | 350℃/662℉ | I-N30AH-N38AH |

I-Curie Temp: ebizwa nangokuthi i-Curie point noma i-magnetic transition point, iwumkhawulo wokushisa ongokomqondo ongokomfanekiso wezinto zikazibuthe, ngale kwezinga lokushisa le-Curie, izici kazibuthe zezinto kazibuthe zizonyamalala ngokuphelele.

I-Max.Working Temp: Uma izinga lokushisa eliphezulu lokusebenza leqiwa, i-magnetism yento kazibuthe izosuswa uzibuthe bese kwenzeka ukulahlekelwa okungenakuhlehliswa.

Ubudlelwano: ukuphakama kwezinga lokushisa kwe-Curie, izinga lokushisa eliphezulu lokusebenza lezinto ezibonakalayo, kanye nezinga lokushisa elingcono kakhulu.

Amandla kazibuthe: Amandla kazibuthe webha yesihlungi kazibuthe ancike ohlotsheni nenani likamazibuthe ngaphakathi kwawo. Amandla kazibuthe anamandla athuthukisa ukusebenza kahle kokuhlunga kodwa angase futhi athinte izinga lokugeleza koketshezi noma igesi.

Impahla: Impahla yesihlungi sikazibuthe kufanele ihambisane noketshezi noma igesi ehlungwayo futhi akufanele ibe ngaphansi kokugqwala.

Ngenxa yokumelana nokugqwala okuhle kakhulu, insimbi engagqwali iyinto esetshenziswa kakhulu ezintweni eziningi. Kodwa-ke, ngezinhlelo zokusebenza ezidinga izinga eliphezulu lokumelana nokugqwala, kubalulekile ngokulinganayo ukukhetha ibanga eliphakeme lensimbi engagqwali. Izibonelo zifaka phakathi i-316 noma 316L, elungele ikakhulukazi izimboni ezifana nokudla noma ukucubungula amakhemikhali, lapho ukuchayeka kumakhemikhali anonya noma umswakama ophezulu kungenzeka.

Uma ungaqiniseki ukuthi iyiphi impahla elungele izidingo zakho zohlelo lokusebenza, sicela ukhululeke ukuxhumana nathi. Ithimba lethu lochwepheshe lingakunikeza iseluleko nesiqondiso sokukusiza wenze isinqumo unolwazi. Kwa-Honsen, sizibophezele ekuqinisekiseni ukuthi uthola okokusebenza okungcono kakhulu kwesicelo sakho, futhi sihlala silapha ukuze sikusize.

Ukufakwa:

Ukuphela kukazibuthe kunezintambo zesilisa

Ukuphela kukazibuthe kunezintambo zesifazane

Iziphetho zikazibuthe zine-welded flat

Zombili iziphetho zikazibuthe zingafakwa ngokwezifiso ukuze zihlangabezane nezidingo zakho ezithile, ngezinketho ezifana nowesilisa, owesifazane, kanye ne-flat weld. Noma ngabe yiziphi izidingo zakho, singakunikeza uzibuthe ofanele ukuqinisekisa inqubo yokufaka engenamthungo.

Ungakhetha kanjani kahle ibha yokuhlunga kazibuthe efanele?

Izinga lokugeleza: Thola izinga lokugeleza nezinga lokushisa lokusebenza okudingeka lihlungwe. Lokhu kusiza ukunquma ukuthi zingaki izinti zokuhlunga kazibuthe ezidingekayo nokuthi yiluphi uhlobo lwezinduku zokuhlunga kazibuthe.

Amandla kazibuthe: Khetha amandla kazibuthe afanele ngokusekelwe ohlotsheni nosayizi wokungcola okufanele kususwe. Ngokuvamile, izinti zokuhlunga kazibuthe ezinamandla ziyadingeka ku-particle enkulu.

Umumo: Khetha umumo ofanele webha yokuhlunga kazibuthe ngokuya ngendawo yangempela yokufaka nezidingo zemishini yesihlungi.

I-Material: Khetha izinto ezifanele ezizofanela imidiya ehlukene ewuketshezi nendawo ezungezile, njengensimbi engagqwali, i-titanium alloy, i-permanent magnetic material, njll.

Izindleko zokuphila nokunakekela: Khetha izinti zokuhlunga kazibuthe ezinempilo ende kanye nezindleko zokunakekela eziphansi ukuze unciphise izindleko zokusebenzisa nezindleko zokuzilungisa.

Ukusetshenziswa kwebha yokuhlunga kazibuthe

Imboni yePlastiki: Izinduku zokuhlunga kazibuthe zivame ukusetshenziswa ohlelweni lokupholisa lwemishini yokubumba umjovo, ama-extruders, imishini yokubumba i- blow kanye nezinye izinto zokususa ama- iron chips, i- iron powder nokunye ukungcola ukuze kuvikelwe ukusebenza okuvamile kwemishini.

Imboni yezemithi: izihlungi zikazibuthe zingasusa ukungcola okufana namashidi ensimbi nama-spikes ensimbi emithini yokwelapha ewuketshezi ukuze kuqinisekiswe ubumsulwa nekhwalithi yezidakamizwa.

Imboni yokudla: Izinti zokuhlunga kazibuthe zisetshenziswa kakhulu emigqeni yokukhiqiza ukudla ukususa ukungcola kwensimbi ekudleni ukuze kuqinisekiswe ikhwalithi nokuphepha kwemikhiqizo.

Imboni yomshini: Izinti zokuhlunga kazibuthe zivame ukusetshenziswa emshinini wokupholisa ama-chips, isihlabathi nokunye ukungcola ukuze kunwetshwe impilo yamathuluzi nokuthuthukisa ukunemba komshini.

Imboni yegesi: Izihlungi zikazibuthe zingasusa ama-iron chips nokunye ukungcola kwegesi yemvelo kanye negesi eliwuketshezi ukuze kuvikelwe ukusebenza okuphephile kwemishini yegesi.

Imboni yamakhemikhali: Isetshenziselwa ukususa izinhlayiya ze-ferromagnetic nama-oxide amiswe esixazululweni.

Imboni yamaphepha: isetshenziselwa ukususa ukungcola kwe-ferromagnetic kunqubo yokwenza iphepha ukuze kuqinisekiswe ikhwalithi yephepha.

Imboni yezimayini: isetshenziselwa ukuhlukanisa amaminerali aqukethe insimbi nensimbi futhi ithuthukise ukusebenza kahle kokucutshungulwa kwezimbiwa.

Imboni yokuhlanza amanzi: izinti zokuhlunga kazibuthe nezinsimbi zingamathuluzi asebenzayo okukhipha insimbi, i-manganese nezinye izinsimbi emanzini, okwenza aphephe ukuphuzwa nokunye ukusetshenziswa.

Imboni yezindwangu: Izinti zokuhlunga kazibuthe kanye nemigoqo kusetshenziswa ekukhiqizeni izindwangu ukususa ukungcola kwensimbi ezindwangu, ukuqinisekisa ikhwalithi yomkhiqizo nokuvimbela ukulimala emishinini.

Imboni yezimoto: Izinti zokuhlunga kazibuthe zisetshenziswa ekukhiqizeni izimoto ukuze kukhishwe izinto ezingcolisa insimbi ezintweni ezipholile kanye nezinto zokugcoba ukuvimbela ukulimala kwemishini nokuqinisekisa ikhwalithi yomkhiqizo.

Izinzuzo Zethu

Thola ibha yokuhlunga kazibuthe eyindilinga ephelele yezidingo zakho! Izinduku zethu kazibuthe ziyatholakala ngesicelo sangokwezifiso.

1.Izinti zethu zokuhlunga kazibuthe namabha zenziwe ngamashubhu ensimbi engenasici yekhwalithi ephezulu futhi ziza nezizibuthe ze-neodymium ezisebenza kahle ukuze zifanele uhlelo lwakho lokusebenza oluthile. Usebenzisa izinti zokuhlunga kazibuthe ezingazodwana, ungakha noma ulungise imishini yakho yokuhlukanisa kazibuthe.

2.Khetha amandla kazibuthe afanele izidingo zakho! Imikhiqizo yethu itholakala ngamandla kazibuthe kusuka ku-1500-14000 gauss ukuze ihlangabezane nezidingo zakho ezithile. Amabha afakwe omazibuthe be-neodymium aqinile angaba namanani kazibuthe afika ku-14,000 gauss endaweni yawo.

3.Ukulingana okuphelele kwezinduku zethu ezivalwe ngokugcwele nezishiselwe! Sinikeza amaphethelo ashiselwe owesilisa, owesimame noma ayisicaba ukuze ahlangabezane nezidingo zakho ezithile.

4.Yonke imigoqo yethu kazibuthe ayinamanzi, iqinisekisa ukuthi isebenza ngokuphumelelayo ngisho nasezindaweni ezimanzi noma ezinomswakama.

5.Imigoqo yethu yokuhlunga kazibuthe nezinduku ziphucuziwe kahle ukuze zinikeze ukubukeka kochwepheshe nokuqinisekisa ukuthi kulula ukuzihlanza nokuyigcina.

Ngezinto zethu zekhwalithi nezinketho eziguquguqukayo, ungakha ngokuzethemba noma uguqule imishini yakho yokuhlukanisa kazibuthe.

Isikhathi sokuthumela: Apr-13-2023