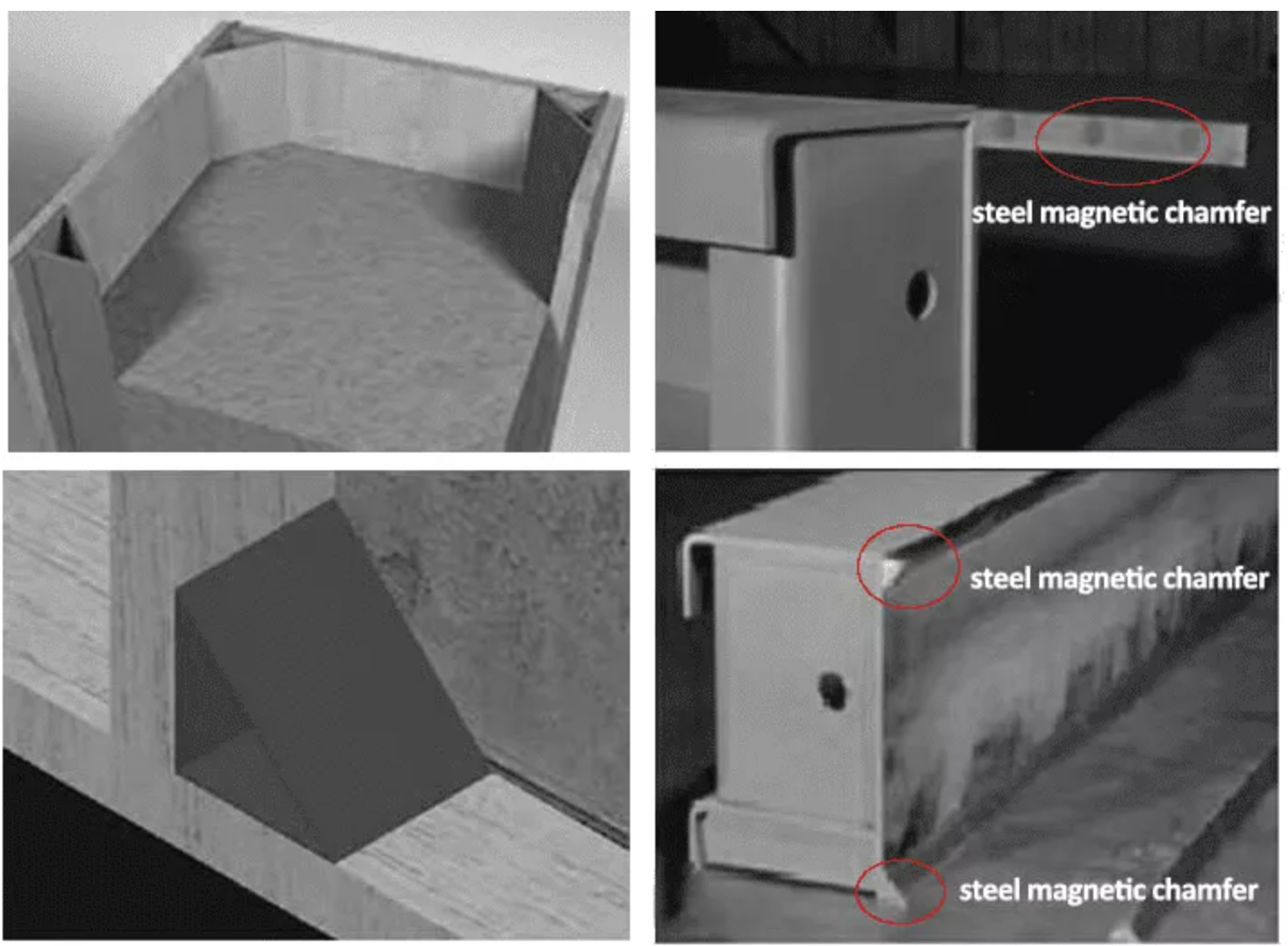

Ukusetshenziswa kwemichilo yensimbi kazibuthe sekusetshenziswe kabanzi embonini kakhonkolo we-precast amashumi eminyaka. Le nto ehlala isikhathi eside iklanyelwe ukumelana nezimo zokusebenza ezidlulele futhi ivamise ukusetshenziselwa ukubamba ngokuphephile izindawo zensimbi. Inhloso yayo eyinhloko ukudala imiphetho enama-beveled emakhoneni e-concrete siding, kanye nezicelo ezithile ze-formwork.

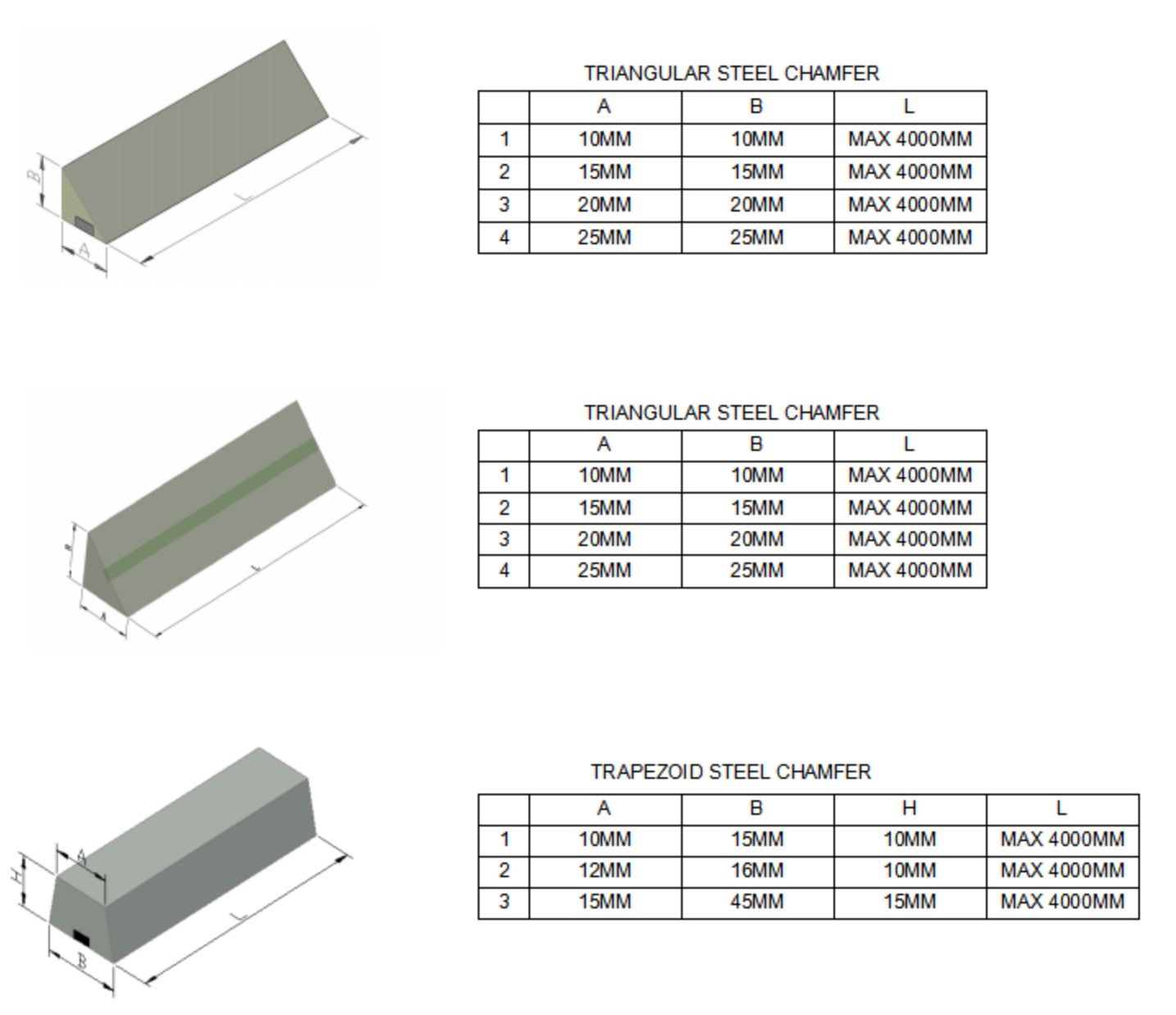

Izimo ezimbili ezivame kakhulu zale micu kazibuthe ngonxantathu kanye nama-trapezoid. Imichilo kazibuthe isiphenduke enye yezesekeli eziguquguqukayo kakhulu embonini kakhonkolo we-precast. Abakhiqizi bangakhetha kosayizi abahlukahlukene futhi babe nenketho yokwenza ngokwezifiso imicu ukuze ihlangabezane nezidingo zabo ezithile. Ukuguquguquka kwalezi ziqeshana kudlulela ekusebenzisaneni kwazo nezakhiwo ezihlukahlukene zekhonkrithi, okuqinisekisa uhla olubanzi lwezinhlelo zokusebenza. Ngaphezu komsebenzi wayo, imichilo ye-magnetic chamfering yensimbi nayo inezinzuzo ezihlukahlukene.

Okokuqala, bahlinzeka ngokunamathela okuqinile ngenxa yezakhiwo zabo kazibuthe, okuholela ekuxhumaneni okuqinile phakathi kwezindawo zekhonkrithi nensimbi. Okwesibili, lezi ziqeshana zihlinzeka ngezindleko kanye nokusebenza kahle kwesikhathi. Inqubo yabo elula yokufaka nokususwa isindisa isikhathi esibalulekile ngesikhathi sokwakha, ngaleyo ndlela kunciphisa izindleko zabasebenzi.

Ukwengeza, ukusebenziseka kwazo kabusha kuqeda isidingo sokushintshwa ngezikhathi ezithile, konga izindleko zesikhathi eside. Esinye isici esiphawulekayo sale micu kazibuthe ukuhambisana kwayo nemiklamo ehlukene yezakhiwo. Zihlangana ngaphandle komthungo ezakhiweni ezihlukahlukene zikakhonkolo, ezithuthukisa ubuhle bomkhiqizo wokugcina.

Le micu iqinisekisa imiphetho enembile futhi enembile ye-chamfered ukuze kuqedwe okupholishiwe nokuchwepheshile. Imichilo yensimbi kazibuthe idlala indima ebalulekile ekuqinisekiseni ubuqotho besakhiwo sezinto zikakhonkolo osakazwa ngaphambili. Ngokwenza imiphetho enama-beveled, anciphisa ubungozi bokuqoshwa futhi anikeze ukumelana nomthelela omkhulu. Lokhu kukhulisa ukuqina nokuhlala isikhathi eside kwesakhiwo sikakhonkolo we-precast, kuqinisekisa ukuzinza nokusebenza kwayo iminyaka ezayo.

I-Magnetic steel chamfering strip isiphenduke insiza ebaluleke kakhulu embonini kakhonkolo we-precast. Ikhono lazo lokumelana nezimo ezibucayi, ukuguquguquka kwazo ngosayizi nokwenza ngokwezifiso, kanye nezinzuzo zazo eziningi kuzenza zibe yingxenye ebalulekile yokwakha izakhiwo zekhwalithi ephezulu zikakhonkolo. Ngokunamathela kwazo okuqinile, izindleko kanye nokusebenza kahle kwesikhathi, ukuhambisana nemiklamo yezakhiwo, kanye negalelo ekuthembekeni kwesakhiwo, le micu kazibuthe iyaqhubeka nokubamba iqhaza elibalulekile embonini yezokwakha.

Khetha ama-chamfer anohlangothi olulodwa uma uhlanganisa izindawo zensimbi eyodwa ngesikhathi, njengamatafula ensimbi noma amaphaneli. Uma usebenza ngezingxenye ezimbili zensimbi ezincikene, khetha i-chamfering ezinhlangothi zombili ukuze uqinisekise ukubekwa okuphephile kwazo zombili izindawo.

Material: Irabha, Q215, Q235 Iron Parts, Neodymium Magnets

Ukwelashwa Okungaphezulu: I-Magnet Zn noma i-NiCuNi Coating

Ukushisa Okuphezulu Okusebenzayo: 80℃

Ukusebenziseka kabusha nokuqina okuhlala isikhathi eside;

Izinto zikamagnetic ezifakwe ngensimbi zinikeza ukunamathela okuphezulu kakhulu;

Ithuthukisa isivuno kanye nekhwalithi yezindonga zikakhonkolo we-precast Ukuphatha kalula ngaphandle kokudonsa uzibuthe ngesikhathi sokusetshenziswa okujwayelekile;

Iqeda imisele edinga ukugcwaliswa kukakhonkolo;

Ukuma okusheshayo nokulula, ukususwa kanye nokuhlanza Ukuma okunembe ku-formwork ngaphandle kwezikulufu, amabhawodi noma ukushisela, ukugwema noma yimuphi umonakalo kuthebula le-formwork;

Idizayinelwe ukuthi ilingane kalula nemibhede yensimbi, amaphaneli ensimbi nazo zonke izinhlobo zamafreyimu wesitimela asakazwa ngaphambili;

Uma kuqhathaniswa nezigxobo zendabuko ezincelisayo, ukumunca okunamandla kuqinisekisa ukuthi izigxobo ezi-chamfering ngeke zinyakaze ngesikhathi sokunisela;

Ukunwetshwa okulula, ukumisa kanye nokukhiqizwa ngobuningi.

- Nakuba ukumuncwa kwemichilo ye-chamfer kungaqinile njengalokho kozibuthe bezifanekiso, kusenenani elifanele lokumunca. Ukusebenzisa kabi kungase kubangele ukulimala komuntu siqu, ukulimala kukazibuthe, noma ukulimala kwendawo yokusebenza. Nakuba izinsimbi zethu kazibuthe zisebenziseka kalula, ukuthatha izinyathelo zokuphepha ezimbalwa ngeke kuvikele wena kuphela kodwa ne-chamfer ngokwayo. Ngezansi, sibeka izincomo zokuphepha ngaphambi, phakathi, nangemuva kokusetshenziswa.

- Gwema ukubeka i-chamfer ibheke phezulu njengoba amandla omthelela angase aphule uzibuthe. Esikhundleni salokho, beka induku ye-chamfer ohlangothini olulodwa kuqala, bese uyibeka kahle endaweni.

- Nakuba omazibuthe nensimbi kwelashwa ukuze kugwenywe ukugqwala, ukuntuleka kokuhlanza okungapheli kungabangela usimende ukuthi unamathele emicu ye-chamfer, okwenza kube nzima ukuyisusa. Ukwandisa impilo ye-chamfer yakho, ihlanze ngemva kokusetshenziswa ngakunye futhi usebenzise amafutha avimbela ukugqwala ukuze uyigcine isesimweni esiphezulu sokusebenza.

- Qiniseka ukuthi izinga lokushisa eliphezulu lokusebenza noma isitoreji lihlala lingaphansi kuka-80°C. Amazinga okushisa aphakeme angase abangele ukuthi imichilo ye-chamfer ibe buthaka noma ilahlekelwe ngokuphelele uzibuthe.

- Kugcine kude nezinto zikagesi (ezifana nomakhalekhukhwini, amakhompyutha aphathekayo, amathebulethi, namakhompyutha) kanye nezinsimbi ze-ferromagnetic ezingadingekile.

- Sebenzisa ukuqapha okukhulu lapho usebenzisa ama-chamfer eduze nabantu abanemishini yenhliziyo. I-chamfer yensimbi engunxantathu idala inkambu kazibuthe enamandla kakhulu engase iphazamise izingxenye ze-elekthronikhi ezingaphakathi kwe-pacemaker.

- Uma kukhona ukhonkolo noma imfucumfucu enamathele ku-chamfer, yisuse ngokushesha. Ukuze uthole amadiphozi kakhonkolo anenkani, wasule kahle noma uwapholise.

- Hlala njalo ugcine itafula lesikhunta libushelelezi. Uma kukhona into eqinile phakathi kukazibuthe netafula lesikhunta, ukumunca okunamandla kungase kubangele ukuthi uzibuthe ukhubazeke.

- Njalo phatha ama-chamfer angamanxantathu ngokucophelela. Uma usuqedile, nqwabelanisa kancane ukuze uvimbele ukukhubeka noma ukumpintsha izandla neminwe ngephutha.

- Sincoma ukuthi ugcine ama-chamfer endaweni yepulasitiki noma yerabha ukuze uqinisekise ukufinyelela okulula.

- Gwema ukuchayeka isikhathi eside elangeni njengoba amazinga okushisa aphezulu angabangela amandla kazibuthe noma ukucishwa ngokuphelele kwamachamfer kazibuthe.

- Gcina izindawo zihlanzekile. Nakuba kokubili uzibuthe nensimbi kwenzelwa ukuvimbela ukugqwala, ukwehluleka ukuhlanza uzibuthe ngendlela efanele kungabangela usimende unamathele emgqeni we-chamfer, okwenza kube nzima ukuwususa. Ngakho-ke, abasebenzisi bayelulekwa ngokuqinile ukuthi bahlanze futhi bagcobe ngemuva kokusetshenziswa ngakunye. Naphezu kokunamathela okumelana nokugqwala ezindaweni zensimbi, ukhonkolo une-alkaline futhi ugqwala, okungabangela ukugqwala ezindaweni zensimbi ngokuhamba kwesikhathi.

Isungulwe eminyakeni eyishumi edlule,I-Honsen Magneticsyigama elaziwayo emkhakheni wezibuthe ezihlala njalo kanye nezingxenye kazibuthe zokukhiqiza nokuthengisa. Ithimba lethu elinolwazi lengamele wonke umjikelezo wokukhiqiza, okuhlanganisa ukukhanda, ukuhlanganisa, ukushisela, nokubumba umjovo. Imikhiqizo yethu ithandwa phesheya kwezilwandle ikakhulukazi eYurophu naseMelika ngezintengo zayo ezincintisanayo, ikhwalithi enhle kakhulu, nokuzibophezela kwethu okungaguquki ensizakalweni egxile kumakhasimende.

- Ngaphezu kweIminyaka engu-10 isipiliyoni embonini yemikhiqizo yamagnetic unomphela

- Kuphelile5000m2 ifektri ifakwe200Imishini ethuthukisiwe

- Yiba aumugqa wokukhiqiza ophelelekusuka kumishini, ukuhlanganisa, ukushisela, ukubumba umjovo

- Iba neqembu eliqinile le-R&D linganikeza okupheleleIsevisi ye-OEM & ODM

-Abasebenzi abanamakhono & ukuthuthukiswa okuqhubekayo

- Ukuthumela okusheshayo nokulethwa komhlaba wonke

- KhonzaONE-STOP-SOLUTION qinisekisa ukuthenga okusebenzayo nokungabizi

- Sebenza namakhasimende amakhulu namancanengaphandle kwe-MOQ

Sizibophezele ekuhlinzekeni ngosizo olubheke phambili kanye nemikhiqizo enobuhlakani, encintisanayo, futhi umgomo wethu uwukuqinisa isikhundla sethu semakethe. Siqhutshwa intuthuko ebalulekile kozibuthe nezingxenye ezihlala njalo, sigxile ekukhuleni ngokuthuthuka kwezobuchwepheshe kanye nokungena ezimakethe ezintsha. Uholwa Unjiniyela Omkhulu, umnyango wethu onamakhono we-R&D usebenzisa amakhono angaphakathi, uhlakulela ubudlelwano bamakhasimende, futhi ulindele izitayela zemakethe ngokubona kusengaphambili. Amaqembu azimele aphatha ngokucophelela amaphrojekthi wamazwe ngamazwe futhi alondoloze uchungechunge oluqhubekayo lomsebenzi wocwaningo.

Ukuphathwa kwekhwalithi kusenhliziyweni yefilosofi yethu yebhizinisi. Sibheka ikhwalithi njengobungqabavu kanye nesimiso esiyisiqondiso senkampani. Ukudlula imibhalo nje, sihlanganisa kalula uhlelo lwethu lokuphatha ikhwalithi ezinqubweni zethu. Lokhu kuqinisekisa ukuthi imikhiqizo yethu ihlangabezana ngokuqhubekayo futhi idlule izidingo zamakhasimende ethu, okubonisa ukuzibophezela kwethu ezingeni eliphezulu.

At I-Honsen Magnetics, izimiso zethu eziyinhloko zikabili: ukuqinisekisa ulwazi lwekhasimende olukhethekile nokugcina ibhentshimakhi yokuphepha engantengantengi. Lezi zimiso zisebenza kumalungu eqembu lethu futhi zisekela ukuthuthukiswa komuntu siqu. Ukukhula kwawo wonke umsebenzi kukhuthaza inqubekelaphambili eqhubekayo yebhizinisi lethu.