Amasistimu we-formwork magnetickungasiza ukwandisa ukusebenza kahle, ukunethezeka, nokuphepha kwabasebenzi embonini kakhonkolo eqinisiwe. Imboni yezokwakha esezisunguliwe ikhula kancane kancane. Imikhiqizo kazibuthe efana nezinhlelo ze-formwork kanye nozibuthe be-ferrule insert isetshenziselwa ukuvikela okufakiwe ku-formwork yensimbi kusetshenziswa odonsa, okuqeda isidingo sokumba. Lezi zinhlelo ezintsha ziguqule ukukhiqizwa kwezinto zikakhonkolo osakazwa ngaphambili. Umazibuthe ungashumekwa ngokuqondile kusifanekiso, esisebenziseka kalula, esisebenza kahle futhi esizinzile. Ukusebenzisa ukunamathela okuqinile okuhlinzekwa yi-block magnetic, i-formwork inamathele ngokuqinile ku-formwork, iqinisekisa ukuzinza kwesistimu ye-formwork engaguquki. Ukuhlanganiswa kwe-formwork yensimbi kanye namabhuloki kazibuthe kuqeda noma yikuphi ukunyakaza okungenzeka njengoba ngisho nokunyakaza okuncane kungabangela ukuguquguquka kwesistimu ye-formwork. Amasistimu kamagnetic formwork asebenziseka kalula, adinga ijika elincane lokufunda, futhi anegalelo elikhulu ekuphepheni nasekuvikelekeni. Imboni yezokwakha esezakhiwe izinzile izinzile. Nge-pry bar ehambisanayo, izibuthe ze-formwork zingaphakanyiswa kalula ukuze zisuse kalula i-formwork yensimbi ku-formwork. Njengoba omagnethi betholakala emiseleni yensimbi ye-formwork, ukuba khona kwezinsalela zikakhonkolo noma ukungcola akubangeli ingozi yokulimala ohlelweni lwe-formwork.

Ozibuthe bethu befomu likakhonkolo wangaphambili bahlanganisa izinto zensimbi kanye nozibuthe abashumekiwe.

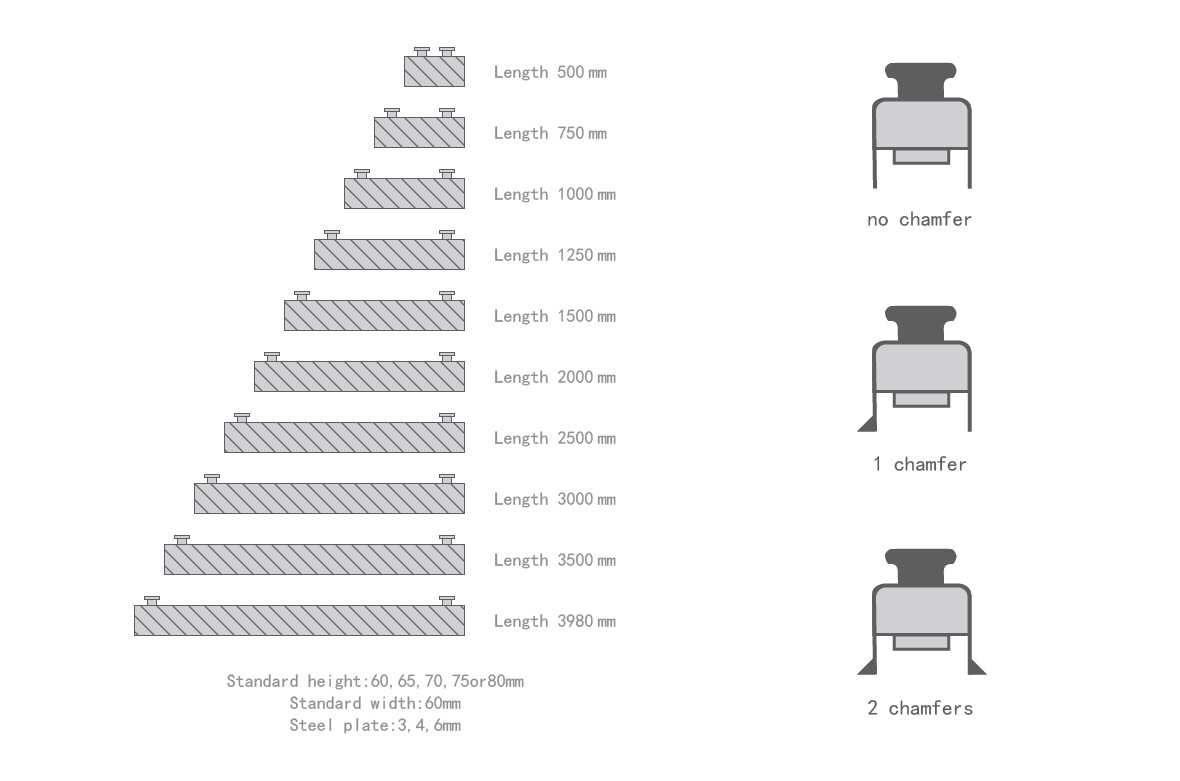

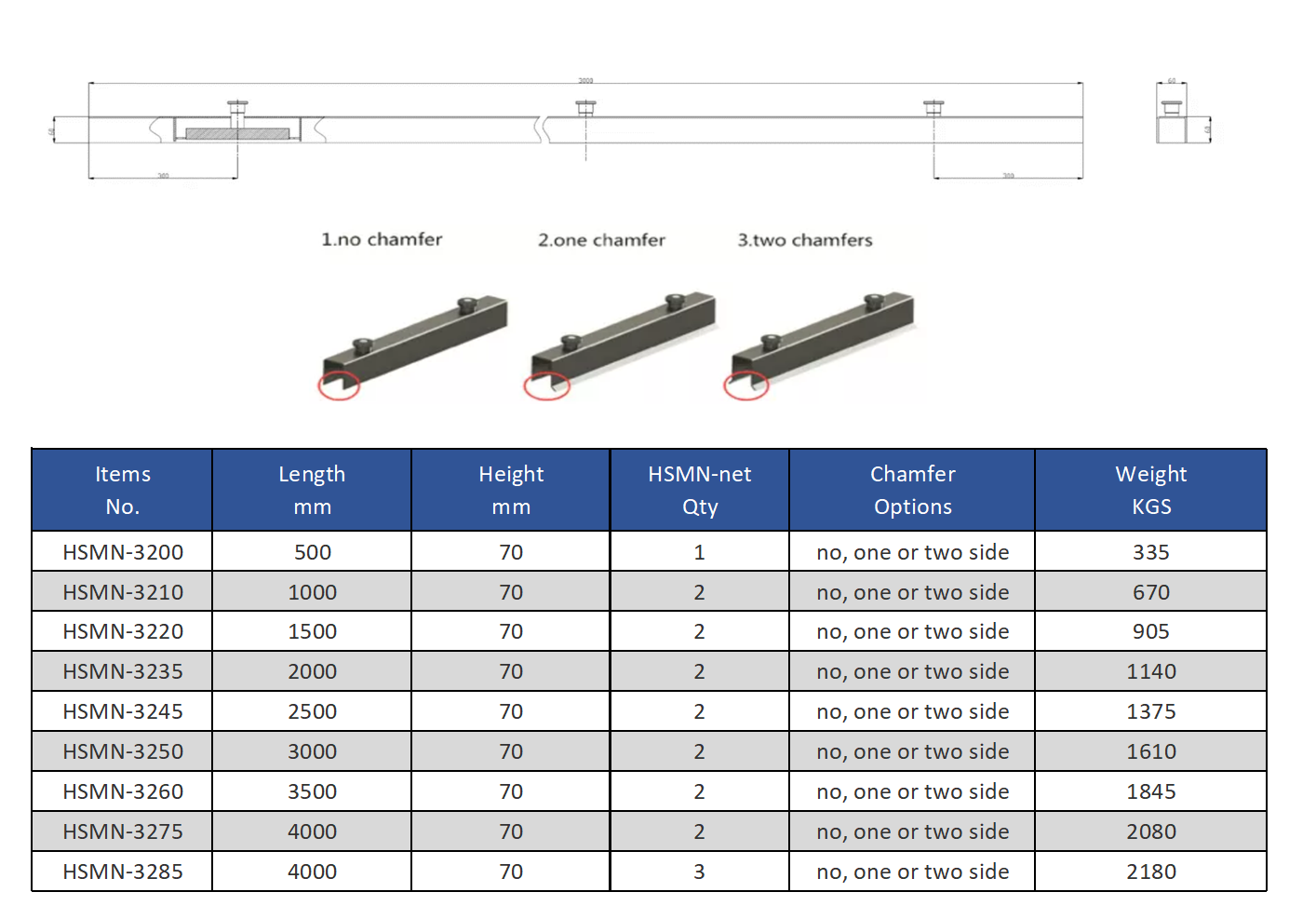

Amasistimu kakhonkolo amise okwe-U aklanyelwe ukucaciswa okuthile. Amakhasimende angakhetha usayizi afiswayo ngemisele noma ngaphandle kwayo nokuthi akhetha i-chamfer eyodwa, ama-chamfer amabili, noma chamfer.

Amasistimu ethu okusebenza kazibuthe enziwe ngokufakwa kukazibuthe okusebenza kahle kakhulu nensimbi yekhwalithi ephezulu. Uhlelo lungafakwa ama-chamfers nhlangothi zombili, ohlangothini olulodwa, noma ngaphandle kwama-chamfers nhlobo.

Siyakwazi ukulungisa isistimu ukuthi ihlangabezane nezidingo eziqondile zobude nobude bamakhasimende ethu. Singakusiza ukuthi uthole isixazululo esifanele sezidingo zakho zokwakha izimboni.

- Kulula ukuthola

- Iyahambisana namarobhothi akhona noma angacushwa ngokucindezela inkinobho

- Umsebenzisi-friendly Iyakwazi ukumelana namazinga okushisa aphezulu

- Imelana nokugqwala Ifanele ukwenza amaphaneli amaseli nezindonga eziphindwe kabili

- Osayizi ngokwezifiso nokuphakama kuyatholakala uma ucela

- Inombolo kamazibuthe ilungiswa ngomsebenzi othile wesifanekiso

- Yakhelwe ukusebenza okuhlala isikhathi eside, okuthembekile, okuqinile

- Ukususwa okulula nge-pry bar ehambisanayo

- Uhlelo oluphelele lwe-formwork lumelana nomonakalo wezinsalela zikakhonkolo nokungcola

- Khetha ku-0 chamfer, 1 chamfer kanye nezinketho ezi-2 ze-chamfer

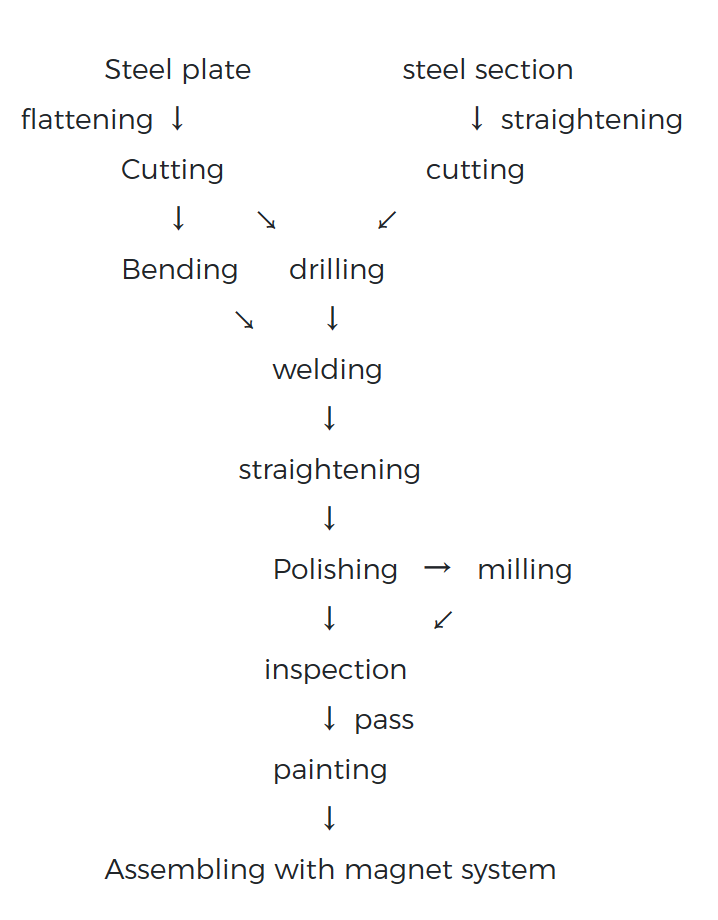

I-formwork formwork yekhonkrithi emise okwe-U ikhiqizwa kusetshenziswa amapuleti ensimbi ngosizo lomshini wokugoqa oyingqayizivele. Indlela yokugoqa inesibopho sokudala inketho ye-double-groove chamfer, i-single-groove chamfer, noma i-chamfer engekho. Siphinde futhi sisebenzise imishini yokunamathisela ngesandla ukuze sithengise omazibuthe be-formwork ngobukhulu obuphakathi kuka-2-3 m. Izikhungo zethu zokukhiqiza ziyakwazi ukukhiqiza omazibuthe bezifanekiso ezinobude obungaphezu kuka-100mm.

Ngezansi ukubuka kabanzi ukuphatha okukhethekile esikusebenzisa ngesikhathi sokukhiqiza ukuze siqinisekise ubude bezinhlelo zikazibuthe zeformwork ozithenga kithi. Sisebenzisa inhlanganisela ye-aluminium alloy nensimbi engagqwali ngokuhlala kwazo okuphakeme nekhono lokumelana nezinga lokushisa elidlulele nokuguga. Ukwengeza, sisebenzisa izindlela zokwelapha ezikhethekile ukuze sivikele amasistimu ethu ekugqwaleni nokugqwala. Lezi zinhlelo kulula kakhulu ukuzinakekela ngoba siwacubungule ngaphambili.

I-Q235A carbon steel inezinto eziphakeme kazibuthe futhi ibiza kakhulu kunensimbi engagqwali. Isetshenziswa kakhulu ekwelapheni kwamakhemikhali. Inhloso yokwelapha okumnyama ukwenza ifilimu ye-oxide endaweni yensimbi ukuze ihlukanise nomoya futhi inikeze umgoqo oqinile wokulwa nokugqwala.

Amanye amakhasimende akhathazekile ngongqimba lwe-oxide oluthinta indawo kasimende. Ukuze siqinisekise ukuphepha kwazo zonke izici zendawo usimende, senze ukwelashwa okukhethekile kokupholisha ku-Q235A carbon steel.

Umazibuthe we-aluminium alloy formwork uqukethe i-aluminium alloy formwork kanye nebhulokhi kazibuthe elishumekiwe. Ngenxa yobuchwepheshe bayo obuyingqayizivele bokucubungula, i-aluminium alloy formwork iqine kakhulu. Iveza ubungozi obuncane bokugoba, ukugoba, noma ukugoba uma kuqhathaniswa nensimbi noma insimbi engagqwali. Ngaphezu kwalokho, i-aluminium alloy inokuvumelana okuhle kakhulu nokuzinza. Isisindo esincishisiwe se-formwork senza kube lula ukuphatha nokusebenzisa.

Ozibuthe bensimbi engagqwali bahlanganisa insimbi engagqwali kanye namabhulokhi kazibuthe ashumekiwe. Ilula futhi kulula ukuyisebenzisa ngengalo yerobhothi.

I-Honsen Magneticsinomlando ocebile weminyaka engaphezu kweshumi ekwakhiweni nasekuhwebeni koZibuthe Abahlala Phakade, Izingxenye Zezibuthe kanye Nokuthengiswa Kwezibuthe. Abasebenzi bethu abanamakhono banomugqa ophelele wokukhiqiza, izinqubo zokuphatha ezinjengomshini, ukuhlanganisa, ukushisela nokubumba umjovo. Isithunzi sethu sakhelwe phezu kwezintengo ezifanele, imikhiqizo yekhwalithi ephezulu kanye nemiqondo egxile kumakhasimende, futhi sijabulela idumela eliphezulu eYurophu naseMelika.

- Ngaphezu kweIminyaka engu-10 isipiliyoni embonini yemikhiqizo yamagnetic unomphela

- Kuphelile5000m2 ifektri ifakwe200Imishini ethuthukisiwe

- Yiba aumugqa wokukhiqiza ophelelekusuka kumishini, ukuhlanganisa, ukushisela, ukubumba umjovo

- Iba neqembu eliqinile le-R&D linganikeza okupheleleIsevisi ye-OEM & ODM

-Abasebenzi abanamakhono & ukuthuthukiswa okuqhubekayo

- Thinakuphelathekelisa imikhiqizo efanelekile kumakhasimende -

- Ukuthumela okusheshayo nokulethwa komhlaba wonke

- KhonzaONE-STOP-SOLUTION qinisekisa ukuthenga okusebenzayo nokungabizi

-Amahora angu-24isevisi eku-inthanethi enempendulo yokuqala

Inhloso yethu eqinile ukuhlinzeka amakhasimende ngosizo olubheke phambili kanye nemikhiqizo emisha, encintisanayo, ngaleyo ndlela siqinise isikhundla sethu emakethe. Siqhutshwa ukutholakala kwempumelelo kozibuthe nezingxenye ezihlala njalo, sigxile ekukhuleni ngokuthuthuka kwezobuchwepheshe kanye nokufinyelela ezimakethe ezingasetshenzisiwe. Umnyango oqinile we-R&D, oholwa unjiniyela omkhulu, usebenzisa amakhono angaphakathi, uhlakulela ubudlelwano bamakhasimende, futhi ubikezela ngokunembile amathrendi emakethe. Iphaneli elizimele liqapha ngokucophelela izinyathelo emhlabeni wonke, ligcina uchungechunge oluqhubekayo lomsebenzi wocwaningo.

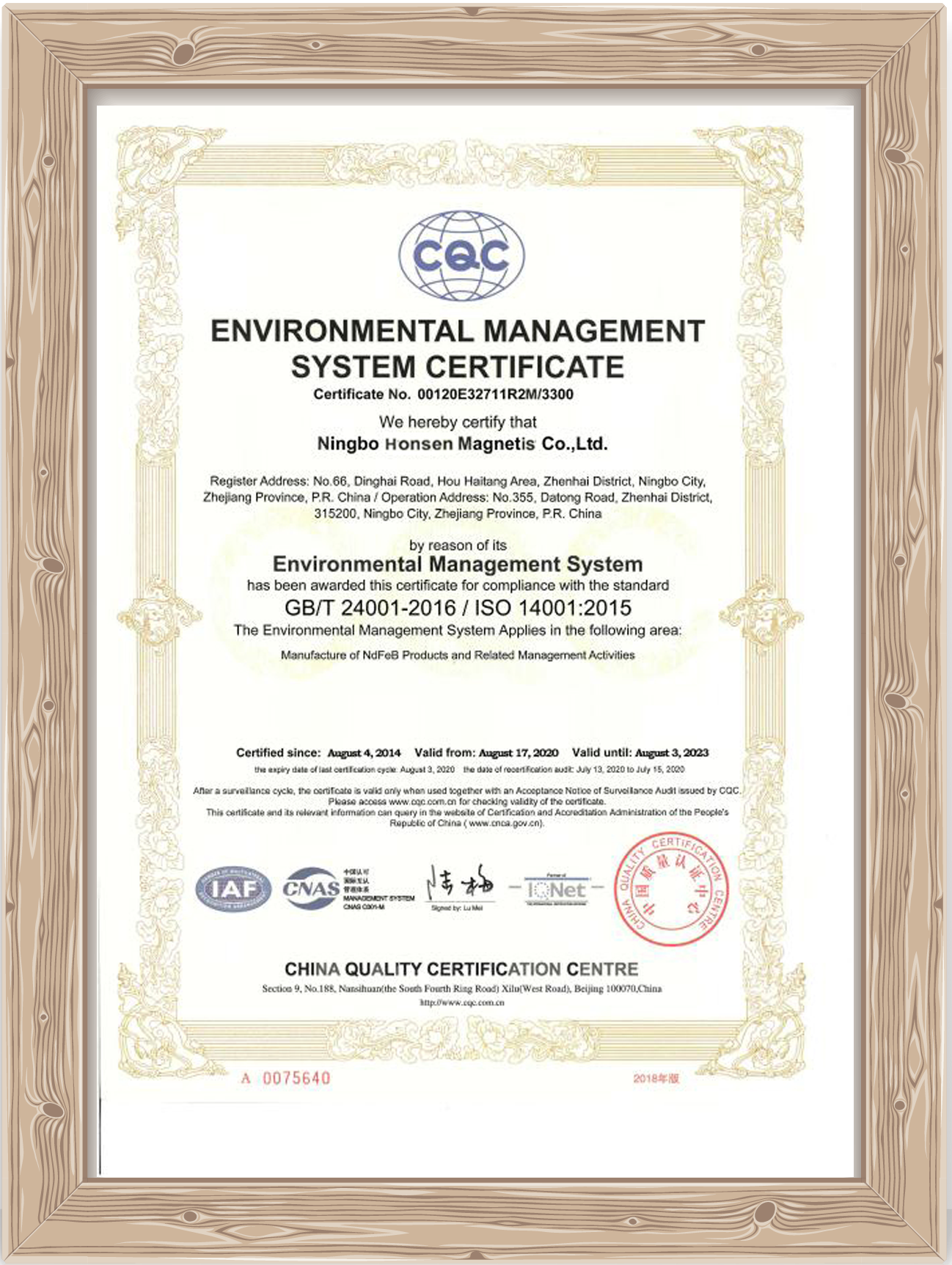

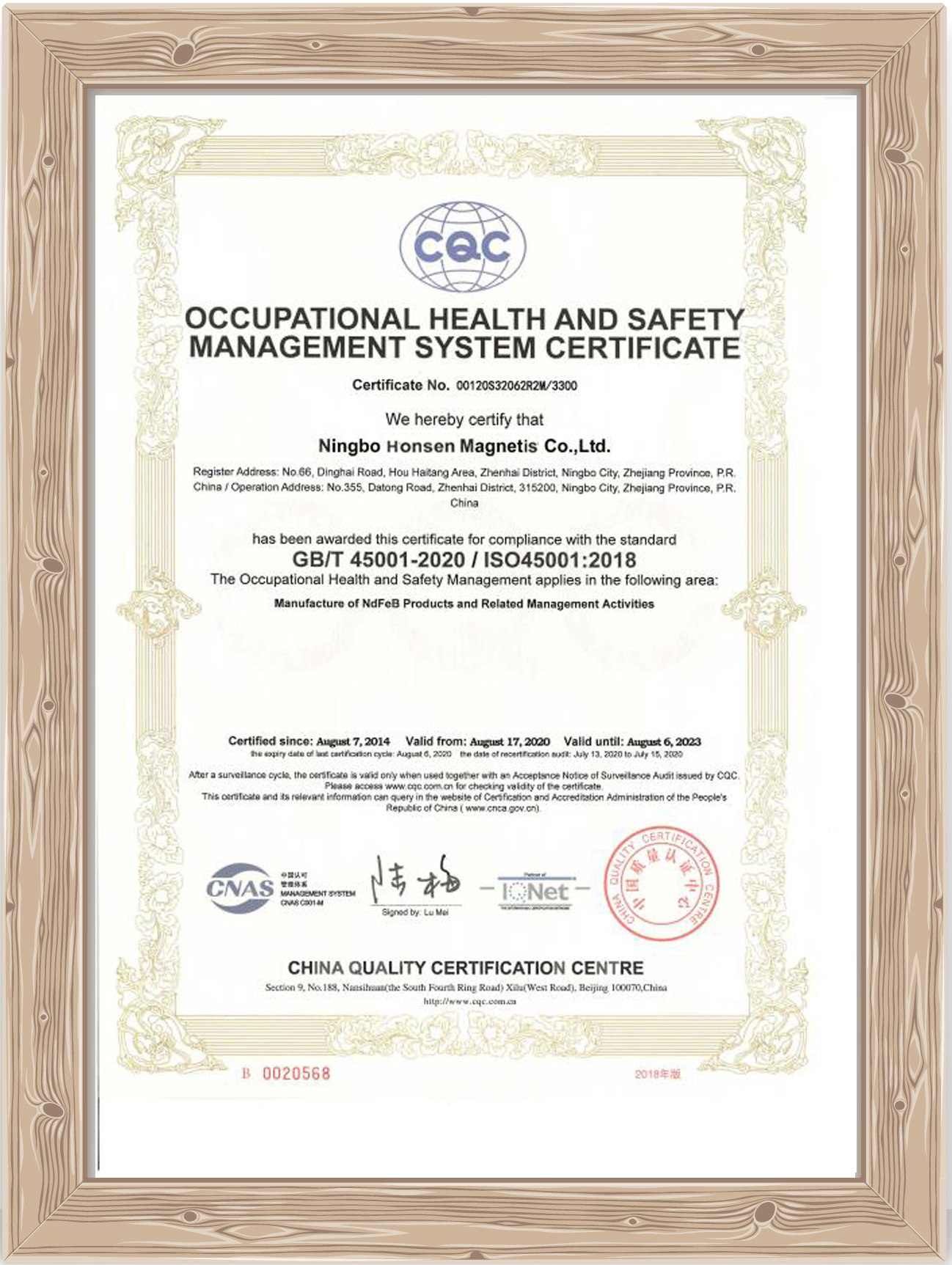

Ukuphathwa kwekhwalithi kuyisisekelo samanani enkampani yethu. Sikholelwa ngokuqinile ukuthi ikhwalithi iyigazi nekhampasi yebhizinisi. Ukuzinikela kwethu kudlula izindlela ezijwayelekile zokuphatha ikhwalithi - kuhlanganiswe nokusebenza kwethu. Ngokusebenzisa le ndlela, siqinisekisa ukuthi imikhiqizo yethu ihlangabezana njalo futhi yeqa izimfuneko zamakhasimende ethu, sibeka amabhentshimakhi amasha ngokwaneliseka.

Inkampani yethu igxile kakhulu ekuphathweni kwekhwalithi. Sikholelwa ukuthi ikhwalithi akuwona nje umqondo, kodwa amandla okuphila kanye nomgomo oqondisayo wenhlangano yethu. Indlela yethu idlulela ngale kwangaphandle - sihlanganisa ngaphandle komthungo isistimu yethu yokuphatha ikhwalithi emisebenzini yethu. Ngale ndlela, siqinisekisa ukuthi imikhiqizo yethu ihlangabezana ngokungaguquki futhi yeqa lokho okulindelwe ngamakhasimende ethu, okubonisa ukuzibophezela kwethu ekwenzeni okuhle.