Kuyini iMagnetic Coupling?

Ukuhlanganisa Magneticwuhlobo olusha lokuhlanganisa oluxhuma umshini ohamba phambili kanye nomshini osebenzayo ngokusebenzisa amandla kazibuthe kazibuthe unomphela. I-Magnetic Coupling ayidingi uxhumano lwemishini eqondile, kodwa isebenzisa ukusebenzisana phakathi kozibuthe basemhlabeni abangajwayelekile, isebenzisa indawo kazibuthe ukuze ingene ebangeni elithile lendawo kanye nezici zezinto ezibonakalayo ukuze kudluliselwe amandla emishini.

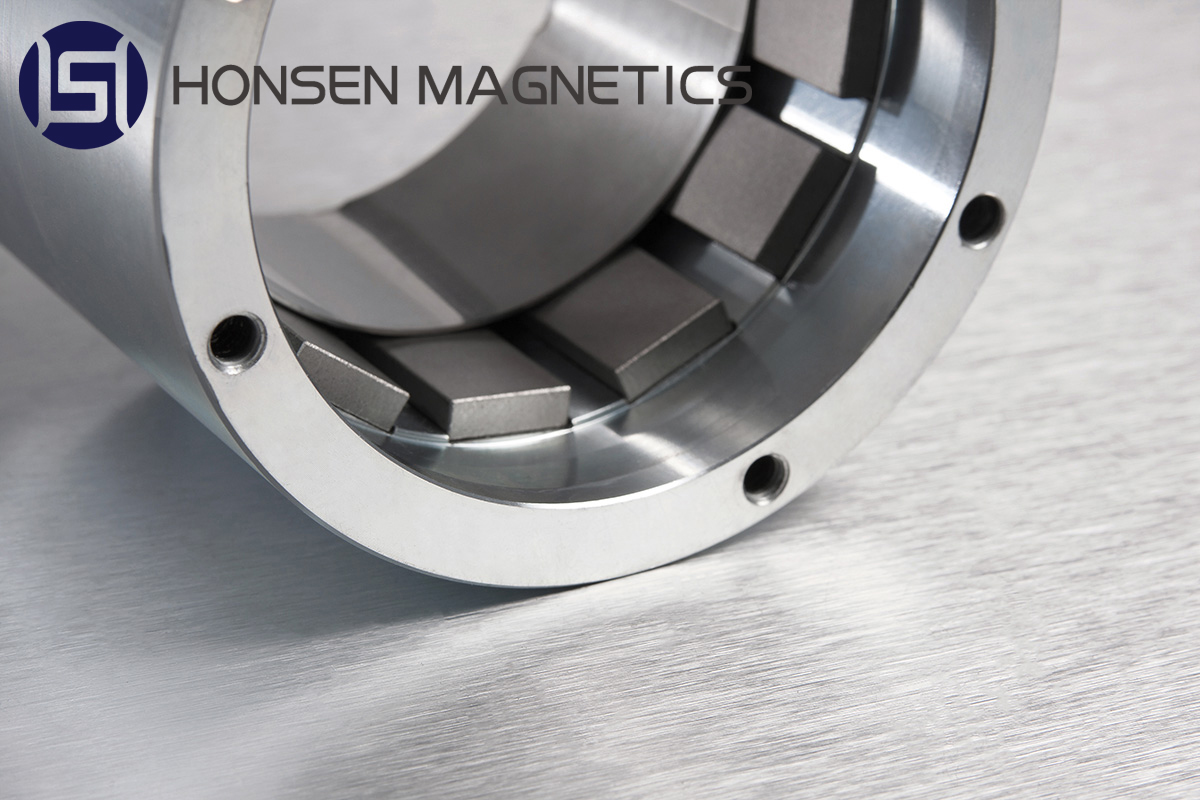

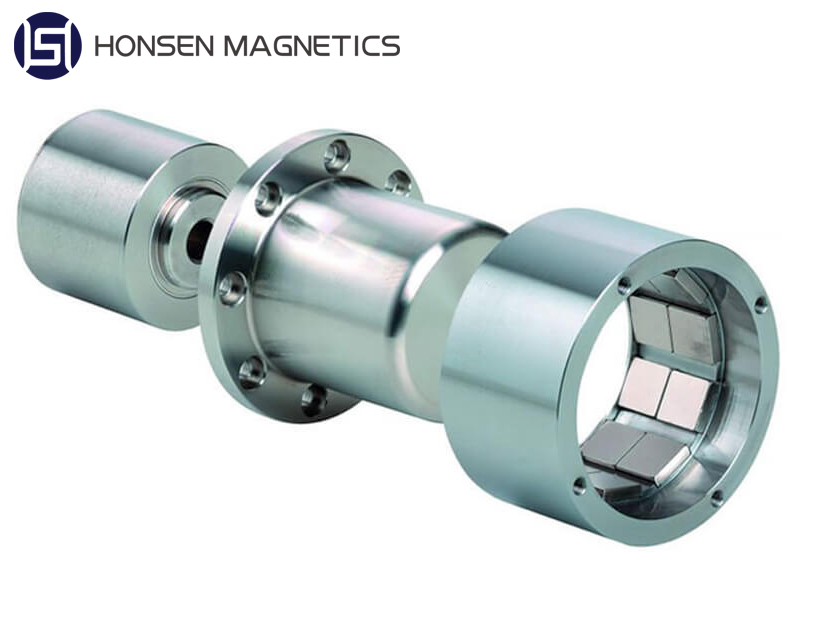

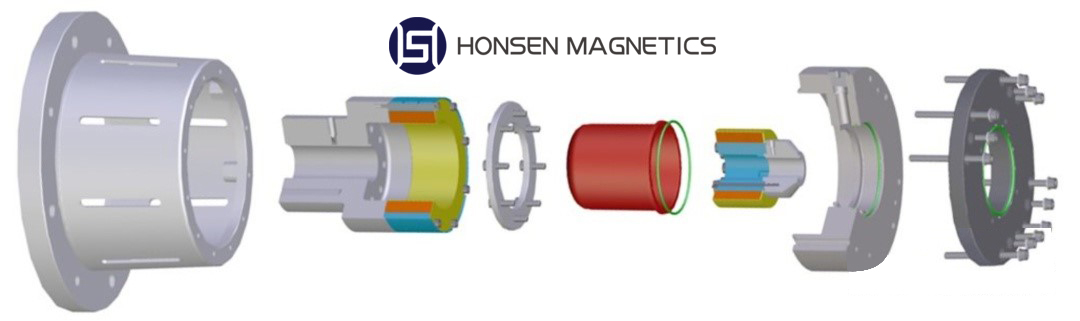

I-coupling kazibuthe ikakhulukazi iqukethe i-rotor yangaphandle, i-rotor yangaphakathi, kanye nekani lokuvala (umkhono wokuhlukanisa). Ama-rotor amabili ahlukaniswe isembozo sokuhlukanisa phakathi, ne-magnet yangaphakathi exhunywe engxenyeni eqhutshwayo kanye ne-magnet yangaphandle exhunywe engxenyeni yamandla.

Ama-coupling kazibuthe angenziwa ngezifiso. Ozibuthe abangapheli ngokuvamile basebenzisaI-SmConomaIzibuthe ze-NdFeB, futhi ibanga elithile lidinga ukunqunywa ngokusekelwe ezingeni lokushisa lokusebenza, indawo yokusebenza, kanye ne-torque yokuhlanganisa. Igobolondo ngokuvamile lenziwa ngensimbi engagqwali (Q235A, 304/316L).

Ama-coupling kazibuthe angasetshenziswa ezinhlotsheni ezihlukene zamaphampu nezixube ezifana namaphampu ngezikulufu, amaphampu egiya, njll. Ukuhlangana kazibuthe kungasetshenziswa ukufeza amaphampu angenasici ukuvimbela umonakalo odalwe imidiya yoketshezi ebolayo edlula kuma-shaft seals. I-Magnetic Couplings ingasetshenziswa futhi ezintweni zikagesi ezingaphansi kwamanzi, njengamaphampu angaphansi kwamanzi, kanye nobuchwepheshe obuhlukahlukene be-vacuum kanye nezinsimbi zokumba uwoyela ojulile olwandle.

Ukuhlukaniswa Kwezinhlanganisela Zezibuthe

- Ihlukaniswa ibe yi-magnetic transmission, ihlukaniswe yaba yi-synchronous transmission (planar ne-coaxial), i-eddy current transmission, kanye ne-hysteresis transmission;

- Ihlukaniswe yaba ukunyakaza okuqondile, ukunyakaza okuzungezayo, nokunyakaza okuyinhlanganisela ngokusekelwe kumodi yokunyakaza kokudlulisela;

- Ihlukaniswe yaba izakhiwo ezihlukene, ingahlukaniswa ngama-cylindrical magnetic couplings kanye nama-flat disk magnetic couplings;

- Ihlukaniswe yaba izimiso ezihlukene zokusebenza, ingahlukaniswa ngokuhlanganisa kazibuthe okuvumelanisa kanye nokuhlanganisa kazibuthe asynchronous.

- Ahlukaniswa ngokwesakhiwo somazibuthe unomphela, ahlukaniswa ngohlobo oluhlakazekile lwegebe kanye nohlobo oluhlanganisiwe lokudonsa.

Yimaphi amapharamitha wobuchwepheshe ayinhloko we-Magnetic Coupling?

Lapho ukhetha ama-coupling kazibuthe, kuyadingeka ukuthi ucubungule ngokujulile izici ezifana nezimo ezithile zohlelo lokusebenza, izici zemoto nezomthwalo, nezidingo zomsebenzi, bese ukhetha amapharamitha obuchwepheshe afanelekile nezikimu zokumisa.

I-Magnetic coupling iyisisetshenziswa sokudlulisa esisebenzisa itorque yamagnetic ukudlulisa itorque, futhi imingcele yayo eyinhloko yobuchwepheshe ihlanganisa izici ezilandelayo:

- I-torque enkulu: imele itorque ephezulu engakhishwa inhlanganisela kazibuthe. Le parameter ihlobene eduze nesimo sohlelo lokusebenza, futhi ngokuvamile, kuyadingeka ukukhetha inani le-torque eliphakeme elifanele ngokusekelwe ezidingweni zangempela.

- Isivinini sokusebenza: simelela isivinini esiphezulu esingabekezelelwa ukuhlangana kazibuthe. Le parameter ithinta ububanzi bokusetshenziswa kokuhlanganisa kazibuthe, futhi ngokuvamile, isivinini sokusebenza esingahlangabezana nezidingo kufanele sikhethwe.

- Ukulahlekelwa kwamandla: Kubhekisela emandleni amuncwa ukuhlangana kazibuthe ukuguqula amandla kazibuthe abe amandla ashisayo noma ezinye izinhlobo zokulahlekelwa. Amandla okulahlekelwa amancane, ayanda ukusebenza kahle kokuhlangana kazibuthe, kanye nemikhiqizo enamandla okulahlekelwa okuphansi kufanele ikhethwe kakhulu ngangokunokwenzeka.

Yiziphi izici zokusebenza zeMagnetic Couplings?

I-Magnet Coupling iwuhlobo lokuhlangana okusekelwe ekudlulisweni kwamandla kazibutheunomphela uzibuthe izinto, enezici zokusebenza ezilandelayo:

- Ukusebenza kahle kokudlulisela phambili: Uma kuqhathaniswa nokuhlangana kwendabuko, ukuhlangana kazibuthe kusebenzisa izinto zikazibuthe unomphela njengemidiya kazibuthe, okuholela ekusebenzeni kahle kokudlulisa, ukufinyelela ngaphezu kwama-99%.

- Ukuminyana kwetorque ephezulu: Ngenxa yomkhiqizo wamandla kazibuthe aphezulu wezinto zikazibuthe ezihlala njalo, ukuhlangana kazibuthe kosayizi ofanayo kungamelana netorque enkulu uma kuqhathaniswa nokuhlangana kwendabuko.

- Ukudluliswa kwe-torque okunembile: I-torque yokudlulisela ye-coupling kazibuthe ihlobene ngokuqondile nesivinini sokufaka, ngakho-ke ingakwazi ukudlulisa ngokunembile i-torque ehlangabezana nezidingo ekusebenzeni okungokoqobo futhi inokuguquguquka okuqinile.

- Ukuqina kukazibuthe okuqinile: Izinto zikazibuthe ezihlala unomphela zinokuzinza okuqinile kanye nokululama kwensimu kazibuthe. Ngisho nasezindaweni zokushisa eziphakeme kanye nomswakama, ngeke kube khona izinguquko kazibuthe, ngakho-ke inokuphila kwenkonzo ende.

- Ukongiwa kwamandla nokuvikelwa kwemvelo: Ngenxa yokusetshenziswa kwamandla kazibuthe ekuhlanganiseni kazibuthe, uma kuqhathaniswa nokudluliswa kwemishini evamile, awakhiqizi ukungqubuzana kwamandla, ukulahlekelwa ukushisa, kanye nokungcoliswa komsindo, ngaleyo ndlela abe nokusebenza okuhle kokulondoloza amandla nokuvikelwa kwemvelo.

Kungani singenza Okungcono

I-Honsen Magneticsigxile ekukhiqizeni nasekukhiqizeniimihlangano kazibuthekanye nokuhlanganisa kazibuthe. Ithimba eliwumgogodla liqukethe ngokuphelele onjiniyela bomklamo wesekethe kazibuthe kanye nonjiniyela bokuklama bemishini. Ngemva kweminyaka eminingi yokuhlanganiswa kwemakethe, sakhe iqembu elivuthiwe: kusukela ekwakhiweni, nasekuthathweni kwesampula kuye kokulethwa kwenqwaba, sinemishini yamathuluzi neyokulungisa ekwazi ukubhekana nokukhiqizwa ngobuningi, eminye yayo eklanywe futhi yakhiwe yithi, Siqeqeshe iqembu. yabasebenzi abanolwazi lokukhiqiza.

Asihlinzeki nje kuphela NGENKONZO EYODWA YOKUMELA yokulethwa kwe-oda lenqwaba yesampula kodwa futhi silwela ukungaguquguquki emikhiqizweni yenqwaba. Sihlose ukuqhubeka sithuthukisa futhi sinciphise ukugxambukela kwabantu ngangokunokwenzeka.

Izinzuzo zethu ekukhiqizeni Magnet Couplings:

- Ujwayelene nezinhlobo ezihlukahlukene zozibuthe, ekwazi ukubala nokwenza kahle iziyingi kazibuthe. Singakwazi ukubala ngokwesilinganiso isifunda kazibuthe. Isibonelo, uma ikhasimende licacisa i-torque ye-coupling kazibuthe unomphela, singanikeza isisombululo esilungile nesishibhile kakhulu ngokusekelwe emiphumeleni yokubala.

- Onjiniyela boMechanical abanolwazi, izici zemishini, ukubekezelelana kobukhulu, nezinye izici zeimihlangano kazibutheaklanywe futhi abuyekezwa yibona. Bazophinde bathuthukise uhlelo lokucubungula olufaneleke kakhulu olususelwe kuzinsiza zesikhungo somshini.

- Ukuphishekela ukungaguquguquki komkhiqizo. Kunezinhlobo ezahlukene zezingxenye kazibuthe kanye nezinqubo eziyinkimbinkimbi, njengenqubo ye-gluing. I-gluing eyenziwa ngesandla ingahluka kumuntu nomuntu, futhi inani leglue alikwazi ukulawulwa. Imishini ezenzakalelayo yokukhipha impahla emakethe ayikwazi ukuzivumelanisa nemikhiqizo yethu. Siklame futhi sakhiqiza isistimu yokusabalalisa yokulawula okuzenzakalelayo ukuze kuqedwe izici zomuntu.

- Abasebenzi abanamakhono kanye nokuqamba okusha okuqhubekayo! Ukuhlanganiswa kokuhlanganisa kazibuthe kanye nemihlangano kazibuthe kudinga izisebenzi zomhlangano ezinekhono. Sidizayine futhi sakha izinto eziningi ezihlukile nezinhle kakhulu kanye namathuluzi ukuze sinciphise izinga labasebenzi, sithuthukise ukusebenza kahle, futhi siphinde siqinisekise ukuhambisana komkhiqizo.

Izinsiza Zethu

Indlela esiyithola ngayo

Ukulalela izidingo zamakhasimende

Ukuze siqonde ngokugcwele izinjongo zekhasimende, ngeke sicabangele kuphela izinkomba zokusebenza ezibalulekile zenhlanganisela kazibuthe kodwa nezinto ezifana nendawo yokusebenza, izindlela zokusetshenziswa, nezimo zokuthutha zomkhiqizo. Ngokuthola ukuqonda okuphelele kwalezi zici, singalungiselela ngempumelelo isigaba esilandelayo samasampula omklamo. Le ndlela ebanzi iqinisekisa ukuthi idizayini yethu ihambisana kahle nezidingo zekhasimende futhi iqinisekisa ukusebenza okuphezulu ezimeni zomhlaba wangempela.

I-Computational Design Model

Siza ekubaleni nasekuklameni amasekhethi kazibuthe ngokusekelwe ezidingweni zekhasimende. Ukucatshangelwa kokuqala kwezinqubo zokucubungula nokuhlanganisa, futhi ngokusekelwe kokuhlangenwe nakho kwethu nemiphumela yokubala, phakamisa iziphakamiso zokuthuthukisa umklamo ongaphelele wekhasimende. Ekugcineni, finyelela isivumelwano nekhasimende futhi usayine isampula ye-oda.

Okokuqala, ngokusekelwe kokuhlangenwe nakho kwethu nokubala okusizwa yi-CAE, kutholwa imodeli efanele. Amaphuzu abalulekile emodeli ukuthi inani lamagnethi kufanele lincishiswe futhi ukwakheka kukazibuthe kufanele kube lula ukuwenza umshini. Ngalesi sisekelo, onjiniyela bacubungula ngokuphelele isakhiwo semodeli ukwenza kube lula ukusicubungula nokuhlanganisa. Hlela imibono yethu futhi uxhumane namakhasimende, futhi ekugcineni usayine ama-oda esampula.

Thuthukisa izinqubo namasampula

Thuthukisa izinqubo ezinemininingwane futhi wandise izindawo zokuqapha ikhwalithi. Umdwebo wokuhlukanisa umkhiqizo wedivayisi kazibuthe usuqalile ukukhiqizwa.

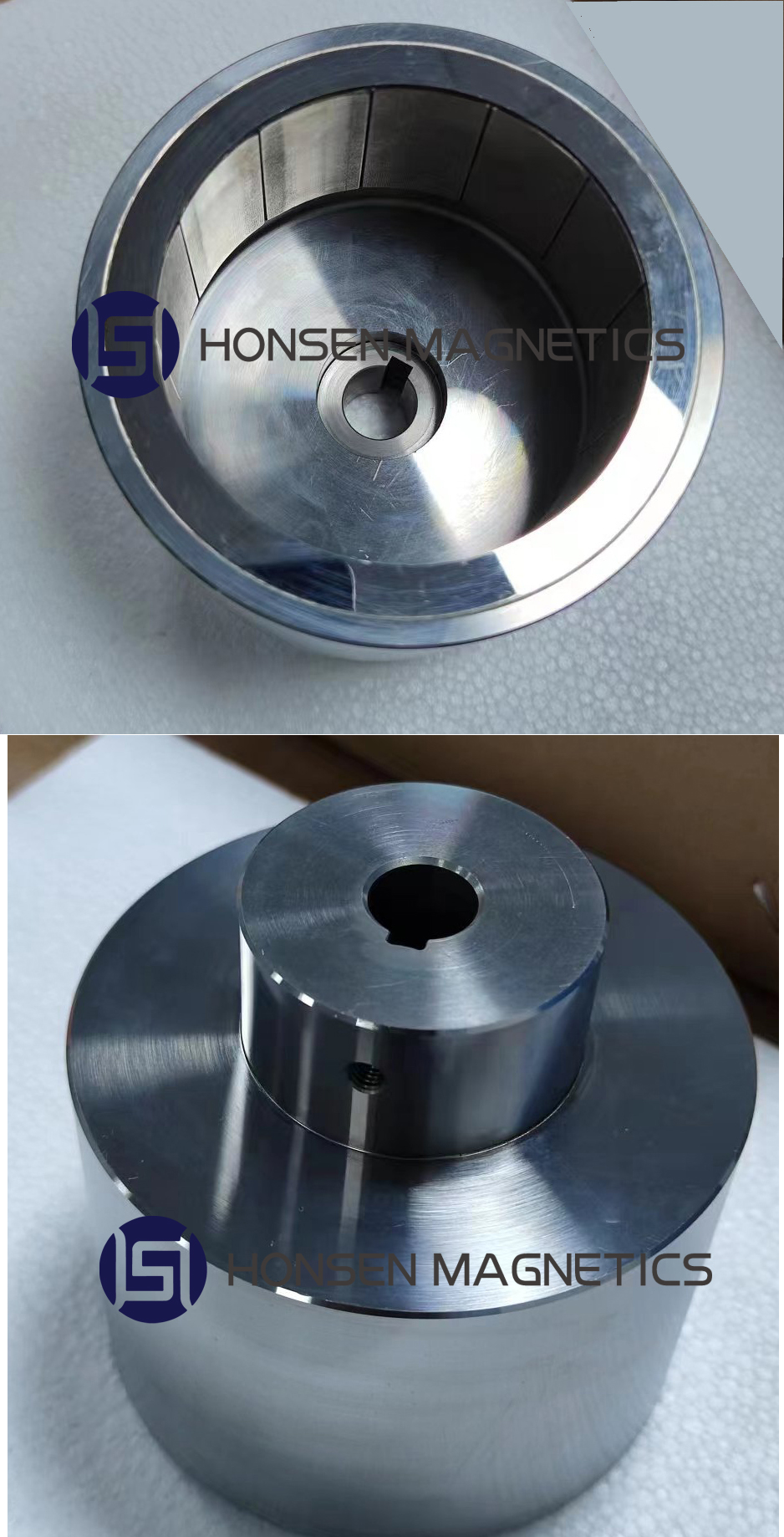

Izakhiwo zokuklama: 1. Qinisekisa ukuma, ukuma, nokubekezelelana kobukhulu bezingxenye; 2. Isetshenziselwa ukulinganisa imishini ukuze kuqinisekiswe ikhwalithi.

Lesi isibonelo sesikhungo sethu sokuhlola esikhethekile esiklanyelwe. Ngemva kokusayina i-oda lesampula, ngokusekelwe kuzici zokucubungula nokuhlanganisa, sidinga ukuthuthukisa izinqubo ezinemininingwane futhi sikhulise ukuqapha kwekhwalithi ezinqubweni ezibalulekile. Ngesikhathi esifanayo, sikhiqiza ama-tooling fixtures. Kulesi sigaba, ithuluzi lisetshenziselwa ukuqinisekisa ukubekezelelana kwejometri ne-dimensional kwezingxenye nawo wonke umkhiqizo, kanye nokuhlolwa kwepharamitha ukuze kuqinisekiswe ukuthi imikhiqizo yethu ingahlolwa ngokushesha nangempumelelo kumaqoqo alandelayo.

Ukulawulwa kokukhiqiza ngobuningi

Ngemva kokuthola ama-oda amaningi, hlela abasebenzi ukuthi basebenze, bahlele ngokunengqondo izindawo zokusebenza nezinqubo, futhi uma kunesidingo, dweba amathuluzi ayingqayizivele okucubungula ukuze kuncishiswe amandla okusebenza nokuqinisekisa ukungaguquguquki ekukhiqizeni inqwaba.

Imishini yokudiliza uzibuthe

Ukuhlanganisa unomphela uzibuthe, ozibuthe bezimoto, nokunye okuhlanganisa kazibuthe kudinga ukuthi omazibuthe bafakwe uzibuthe ngaphambi kokuhlanganisa. Ukuqaqa odonsa ngesandla akusebenzi kahle, futhi into ebaluleke kakhulu ukuthi kubuhlungu ukukhipha odonsa ngeminwe isikhathi eside. Ngakho-ke, siklame futhi sakha le mishini encane ukuze ikhulule ngokuphelele ubuhlungu bezisebenzi futhi sithuthukise ukusebenza kahle.

Imishini yokunamathisela ezenzakalelayo

Ukuhlangana okuningi kazibuthe kanye nezingxenye kudinga ukusetshenziswa kweglue ukuhlanganisa omazibuthe abanamandla nezinye izakhi ndawonye. Ngokungafani ne-gluing manual, inani leglue alikwazi ukulawulwa. Sidizayine futhi sakha izinto zokunamathisela ezizenzakalelayo eziqondene ngqo nemikhiqizo yethu, esebenza kahle kakhulu futhi esebenza kahle uma iqhathaniswa nemishini ethengiswa emakethe.

I-laser welding ezenzakalelayo

Imikhiqizo yethu eminingi yama-oda idinga i-laser welding yezingcezu zokusebenza ngenjongo yokuvala (ezinye izingxenye kazibuthe zidinga ukuthi uzibuthe uvalwe ngokuphelele). Ekushiseleni kwangempela, ama-workpieces anokubekezela futhi kukhona ukuguqulwa okushisayo ngesikhathi sokushisela; Akusebenzi ukushisela ama-oda amanani amakhulu. Sidizayine futhi sakha izakhiwo eziningi ezikhethekile ukuze sikwazi abasaqalayo ukuthi baqale ngokushesha.

Sinolwazi olubanzi ekulawuleni ukukhiqiza, futhi sidinga ukuzuza ukulawula okungalinganiseka kuzo zonke izinqubo ukuze siqinisekise ukufana kuqoqo ngalinye lemikhiqizo.

UKUPAKA NOKUDILIVA

Q&A

Q: Ingabe ikhona imidwebo?

A: Sithuthukise futhi saklama ubukhulu bochungechunge bokuhlanganisa, futhi amakhasimende angenza izinguquko ngokusekelwe kulokhu. Futhi samukela amakhasimende ethu nganoma yimaphi amaphrojekthi enziwe ngokwezifiso.

Q: Ithini isampuli, intengo, nesikhathi sokuhola?

A: Ekuqaleni kwephrojekthi yokuhlanganisa kazibuthe, ukuhlolwa kwesampula kuhlala kudingekile, ngakho samukela ama-oda esampula. Nokho, ukuze sihlole amakhasimende anezinjongo zeqoqo, sizokhokhisa inkokhelo yesampula ephezulu. Sizokhokhisa imali eyisampula esukela ku-3000 kuya ku-8000 yuan ngetorque kusuka ku-0.1 Nm kuya ku-80 Nm, futhi isikhathi sokulethwa ngokuvamile siyizinsuku ezingama-35 kuya kwezingu-40.

Q: Kuthiwani ngenqwaba ye-MOQ kanye nenani?

A: Ngokusekelwe ebunzimeni obuthile bokucubungula, yenza izahlulelo ezihlosiwe nezicaphuni.

Q: Ingabe unayo i-inventory?

A: Ukuhlanganisa kazibuthe ngokuvamile kwenziwa ngezifiso. Isibonelo, uma amakhasimende edinga izimbobo ze-shaft ezihlukene, sidinga ukulungisa kabusha izingxenye, ukuze singagcini imikhiqizo eqediwe. Konke ukukhiqizwa okwenziwe ngezifiso, akukho mpahla.

Q: Ingabe ukuhlanganisa kazibuthe kuzolahlekelwa ukusebenza kazibuthe?

A: Izixhumi kazibuthe zisebenzisa ozibuthe unomphela ukudlulisa i-torque ngaphandle kwezikhala. Uma uzibuthe unomphela eyeka uzibuthe noma elahlekelwa injabulo, ukuhlangana kazibuthe kungasebenzi. Izindlela eziyinhloko zokuqeda uzibuthe zikazibuthe unomphela zifaka izinga lokushisa eliphezulu, ukudlidliza, indawo kazibuthe ehlehlayo, njll. Ngakho-ke, ukuhlangana kwethu kazibuthe kufanele kusebenze esimweni sokuvumelanisa samarotha angaphakathi nangaphandle. Uma umthwalo umkhulu kakhulu, i-rotor yangaphandle ilayisha ngokuphindaphindiwe inkambu kazibuthe ebuyela emuva ku-rotor yangaphakathi, ekhishwa kalula uzibuthe, okuholela ekuncishisweni kwetorque noma ukwehluleka okuphelele.

Q: Yini okufanele ngiyinake lapho ngifaka i-coupling kazibuthe?

A: I-coupling kazibuthe iyi-transmission engeyona yokuxhumana, enegebe elithile phakathi kwe-rotor yangaphandle kanye nomkhono wokuhlukanisa, kanye naphakathi komkhono wokuhlukanisa kanye ne-rotor yangaphakathi, kunciphisa kakhulu ubunzima bokufaka. Kodwa-ke, ubukhulu bodonga lomkhono wokuhlukanisa buncane kakhulu, futhi uma bushayisana nezinye izingxenye noma izinhlayiya eziqinile ngesikhathi sokusebenza, kuzolimaza umkhono wokuhlukanisa futhi kuhluleke ukusebenza njengophawu. Ngakho-ke, kuyadingeka ukuqinisekisa izinga elithile le-coaxiality ngokusho kwezimvume ezahlukene.

Q: Ungakhetha kanjani imodeli?

A: Okokuqala, thola i-torque ye-coupling encane ngokusekelwe kumandla alinganiselwe kanye nesivinini esilinganiselwe senjini. Ifomula yokubala emangelengele i-coupling torque (Nm)=10000 * amandla emoto (kW)/isivinini semoto (RPM); Okwesibili, kuyadingeka ukuqonda izinga lokushisa lokusebenza, ingcindezi yokusebenza, kanye ne-anti-corrosion ephakathi. Ukuhlanganisa kwethu kazibuthe kudinga isivinini esingaphansi kuka-3000RPM kanye nengcindezi yokusebenza engaphansi kuka-2MPa.

Q: Isebenza kanjani inhlanganisela kazibuthe unomphela?

A: I-Magnet Couplings nayo iyatholakala ngezindlela ezihlukahlukene zesakhiwo. Izixhumi zethu zikazibuthe unomphela zisebenzisa isimiso samazibuthe aqinile adonselana ngokungeyena othintana naye. Yakhiwe ngamarotha angaphakathi nangaphandle, ahlanganiswe nozibuthe abaqine kakhulu. I-motor ishayela i-rotor yangaphandle ukuze ijikeleze ngenkathi idlulisela amandla e-kinetic ku-rotor yangaphakathi ngokusebenzisa umjikelezo kazibuthe we-rotor yangaphakathi nangaphandle, okwenza i-rotor yangaphakathi ijikeleze ngokuhambisanayo. Lolu hlobo lokuhlanganisa kazibuthe lufinyelela ukuvaleka okumile ngenxa yokuntuleka kokuxhumana okuqinile phakathi kwamashafu okudlulisela angaphakathi nangaphandle futhi lisetshenziswa kakhulu ezinhlelweni zokudlulisela uketshezi noma amagesi abolayo, anobuthi, nokungcola.